TIX404-ORA-WHITE

Single Color Interchangeable Thru-Hull

10 - 31 VOLT

IP-68

Before you Start

www.Lumishore.com

45-0183 - Rev 1.0

Lumishore UK Unit 2, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | [email protected]

1

INSTALLATION AND OPERATION INSTRUCTIONS

Congratulations! You have purchased a LUMISHORE advanced LED

technology underwater lighting system. Every care has been taken to

ensure your compact TIX 404 LED lights arrives in perfect condition,

so please enjoy the ultimate experience in underwater lighting.

Please read the following pages to ensure a complete understanding

of the LUMISHORE LED lighting system before installation.

•

Always ensure that the vessel’s power source and battery are

disconnected or isolated prior to installation

• A qualified professional should carry out both the electrical and

mechanical installation.

• For best underwater illumination, LUMISHORE recommends instal-

lation 4” to 12” (100-300mm) below the minimum load water line.

• Choose a location - The light must be mounted on a flat (not

curved) surface. For underwater installs mount on transom or side

hull only.

• A hole will be drilled to allow the light to be inserted; care must be

taken to ensure there is unrestricted access inside the hull.

• When installing three or more lights, equal spacing 2.5’- 3’ is recom-

mended to give a consistent light pool.

• The light is temperature sensitive and must not be located close to

the exhaust outlet or other heat source.

• Each light should be individually fused 12VDC - 6A, or 24VDC - 4A

fuse.

• For Metal Hull or Carbon Fibre installations an Isolation Kit

(60-0210) will be required.

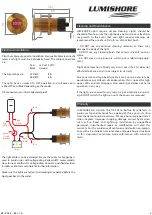

Mechanical Installation

Tools: Drill, drill bits, marine sealant (Use 3M 4200 (recommended) or

similar), 5mm Allen wrench, rags for clean-up:

Hole Cut Out - 57 mm (2.25“) - With isolation Kit - 64mm (2.5 “)

1. Measure the position of the lights on a flat part of the hull.

Mark carefully, and double-check for internal obstacles.

2. Drill a perpendicular hole through the hull using an appropri-

ate cutter for the hull material. The hole should be the size given

above.

3. The exposed inner hull surface must be properly sealed to

prevent water intrusion into the hull before the Thru-Hull is

secured in place.

4. Before inserting the Thru-Hull light ensure that the hull

surface is free from dirt and grease and remove any existing

anti-foul from the hull surface

5. Remove the washer and nut from the shaft of the light. Using

an approved adhesive (3M 4200 Marine (recommended) or

similar). Apply a liberal amount of sealant in a continuous bead

around the entire circumference of the sealant groove, and on

the base of the stem and on the shaft of the Thru-Hull.

6. Feed the cable through the hole in the hull avoiding any strain

on the cable. Gently insert the stem of the Thru-Hull light assem-

bly through the hole in the hull.

7. Apply even pressure with a slight circular motion until the

Thru-Hull is flush with the hull surface.

8. From inside the vessel, feed the supplied washer down the

shaft of the Thru-Hull fitting. Screw the locking nut in place

and tighten the retaining bolts so that they are hand tight (less

than 1Nm) -

Do not tighten fully at this stage, excess pressure

will push all of the sealant out.

9. Remove excess sealant that is squeezed from behind the light

with a rag. Use a damp cloth to wipe off excess sealant that has

squeezed out around the light. DO NOT use chemical cleaners or

solvents.

10. Allow the sealant to cure according to the sealant manufac-

turer’s instructions. Once fully cured, using a 5mm Allen wrench,

re-tighten each retaining bolt (force less than

3Nm

).

Care

should be taken not to exceed this force as damage to the

light module or hull of the vessel may occur.

11. Attach the vessel’s bonding protection to the bonding bolt

on the locking ring.

Rear Side

Apply a liberal

amount of sealant

45-0183 Rev 1.0

Single Color Interchangeable

Thru-Hull Underwater Light