Lucent Technologies Lineage

®

2000 100A Ferroresonant Rectifier J85503A-1

5 - 12 Installation

Issue 6 October 1998

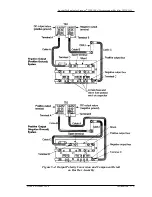

4. Tape or otherwise insulate the connectors on the end of

each cable that does not terminate in the rectifier.

5. Place dc return cable in cable rack.

6. Thread end of cable through right side of rectifier and

terminate connector at the appropriate ground bus bar in

the rectifier. The ground bus bar is positive for negative

output voltage plants, and negative for positive output

voltage plants. Torque connection to 120 in-lbs. See Figure

5-2.

7. Remove tape or insulation from connector at other end of

cable and terminate on plant charge ground bus bar.

8. Place dc output cable in cable rack.

9. Thread end of output cable through right side of rectifier

and terminate connector on dc output bus bar in rectifier.

Torque to 120 in-lbs. See Figure 5-2.

10. Remove tape or insulation from connector at other end of

output cable, and terminate connector on (hot) charge bus

bar.

Install Plant

Control Cable

Assembly for a

Lucent

Technologies

Controller

The Plant Control Cable Assembly has a 24-pin or 16-pin

connector on one end and a 40-pin connector on the other end.

The 24-pin or 16-pin end terminates on the battery plant

controller and the 40-pin end terminates on connector P2A of the

CM2 control board located in the rectifier (see Figure 5-2).

1. Route the plant control cable from the controller chassis

via the cable racks to the rectifier, then through the

opening provided for this cable (see Figure 5-1).

2. Terminate the 40-pin connector on P2A of CM2 and dress

cable (using strain relief bushings and cable ties provided)

inside rectifier allowing for the door to be opened and

Warning

Avoid arc or sparks. Before making contact between

connectors and the output bus bar in the next step, use a DMM

to verify a true open circuit between connector and known

battery plant ground.