1. Product Components and Signals

1-7

1.2

System Configuration

1.2.1

Overview

The L7 servo system can be configured in various ways depending on its interface with the

upper level controller.

(1)

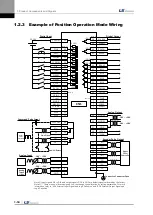

Position Operation System

The servo is run by pulse commands. You can change the location of the servo motor by

changing command pulses based on a certain transfer unit.

Position

Controller

Speed

Controller

Change

Position

Command

Pulse

Position

Controller

Speed

Controller

Current

Controller

Position Controller

Upper Level Controller

Servo Drive

Servo Motor

Motor

Encoder

Position Feedback

Advantage: The structure of the upper level controller is simple because pulse input is linked to

transfer units.

Disadvantages:

Fast rotation is compromised when a precise transfer unit is used.

Response is low because multiple levels of controllers are used.

(2)

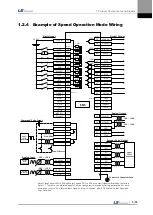

Speed Operation System

The servo is run by speed commands. There are two types of speed commands: analog

voltage command and digital speed command.

Position

Controller

Speed

Controller

Change

Speed

Command

Speed

Controller

Current

Controller

Speed Command

Upper Level Controller

Servo Drive

Servo Motor

Motor

Encoder

Position Feedback

Advantages:

The servo responds quickly.

Precision control is easy.

Disadvantage: The upper level controller is complex.

Summary of Contents for L7 A001

Page 1: ...VER 1 5...

Page 2: ......

Page 32: ...1 Product Components and Signals 1 20...

Page 38: ...2 Installation 2 6...

Page 54: ......

Page 188: ...7 Product Specifications 7 26 L7 A020 L7 A035 Weight 2 5 kg cooling fan included...

Page 210: ...8 Maintenance and Inspection 8 14...

Page 211: ...9 Appendix 9 1 9 Appendix...

Page 218: ...9 Appendix 9 8...

Page 221: ......

Page 222: ......