Chapter 7. Diagnosis Function

7-6

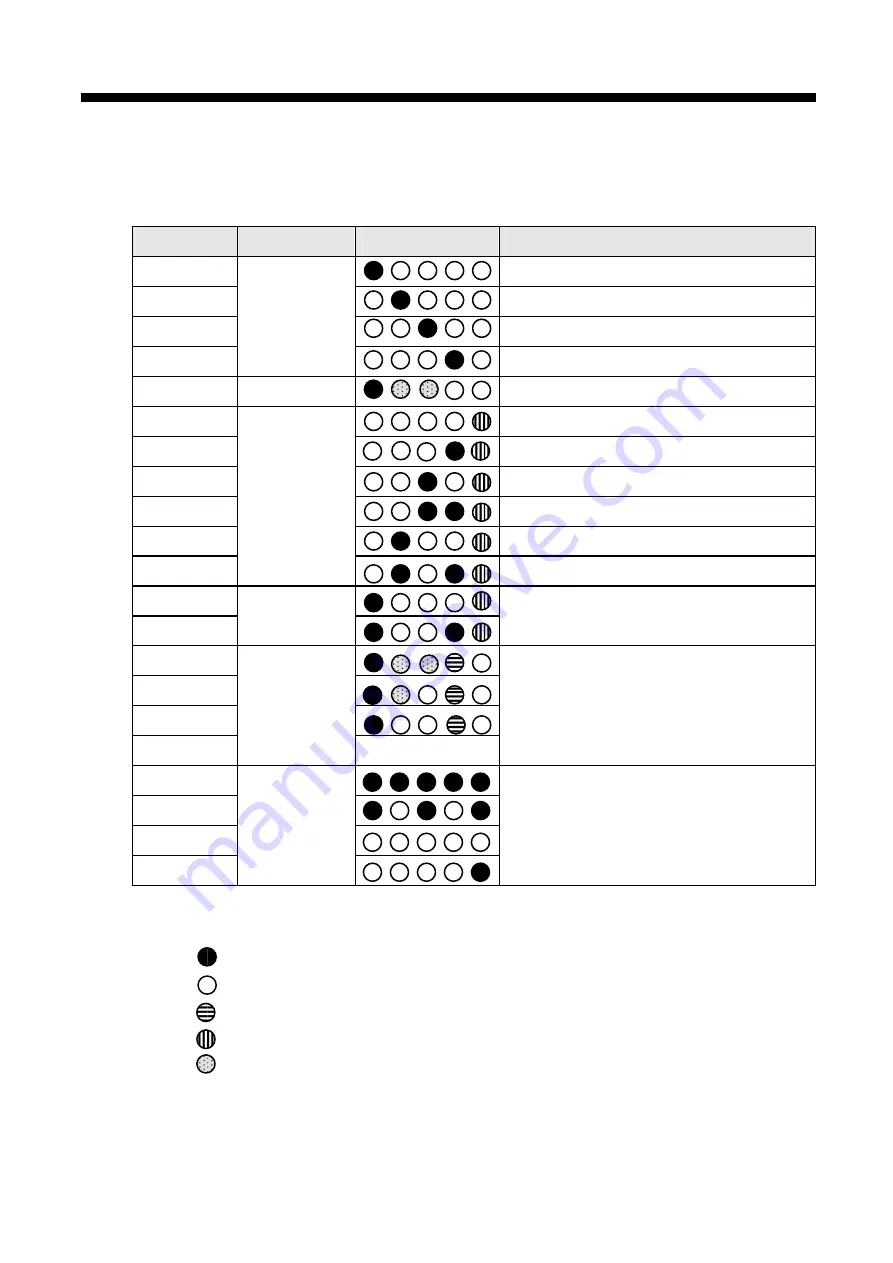

[Table 7.1.3] LED indication specification of slave group

Classification

Error type

LED status

Error contents

RSM_00

Checking inner memory 1 of module

RSM_01

Checking inner memory 2 of module

RSM_02

Checking

communication

RSM_03

Power on

Checking special module common RAM

RSM_04

Normal

Module communication is normal

RSM_05

Inner memory 1 error

RSM_06

Inner memory 2 error

RSM_07

Communication

error

RSM_08

Write/Read special module error

RSM_09

Write/Read I/O module error

RSM_10

Hardware error

Module equipment error, fuse error

RSM_11

RSM_12

System

operation error

System error during operation

RSM_13

RSM_14

RSM_15

RSM_16

Abnormal

①

Cable shout/open

②

Not suitable for cable length

③

Hardware error

④

Network configuration status error

RSM_17

RSM_18

RSM_19

RSM_20

Error that

can

’

t be

recovered

Hardware error of communication module

※

LED location is RUN, TOKEN, TX/RX, FAULT, SYS FAULT from left.

On

Off

Flicker with 1 second period

Non-periodical flicker or off

Non-periodical flicker