22

Instruction Manual

4.6 FASTPRIME™ VALVE ASSEMBLY

O-RING REPLACEMENT

ALWAYS WEAR PROTECTIVE

CLOTHING, FACE SHIELD,

SAFETY GLASSES AND GLOVES WHEN PERFORMING

ANY MAINTENANCE OR REPLACEMENT ON YOUR PUMP.

Refer to the LMI

®

Metering Pump Price List for

the proper Spare Parts Kit or RPM PRO PAC™

kit number or contact your local LMI

®

stocking

distributor.

1. Be sure the Injection Check Valve is properly

installed and is operating. If a shut-OFF valve

has been installed downstream of the Injection

Valve, it should be closed.

BE SURE YOUR RELIEF

TUBING IS CONNECTED TO

YOUR FASTPRIME™ VALVE AND RUNS BACK TO YOUR

SOLUTION DRUM OR TANK.

2. Turn the FASTPRIME™ Knob one-and-a-

half turns counter-clockwise

Q

. This will

depressurize the head. Keep valve open.

Carefully remove the return line by gently

pulling tubing and moving it from side to side

to gradually back tubing OFF of the barbed

fitting.

3. Hold return line tubing upright until solution

drains back into solution drum or tank.

4. Using a 3/4” (or 19 mm) socket or wrench

remove Retaining Nut and pull out the entire

FASTPRIME™ Valve assembly. Remove and

replace the two small O-rings.

5. Reinsert the FASTPRIME™ Valve assembly

and retighten the Retaining Nut. Then turn the

FASTPRIME™ Knob clockwise

P

to tighten

knob to the closed position. To avoid damaging

the parts, it is important that the flange on the

FASTPRIME™ Valve is flush with the Retaining

Nut prior to reassembly.

6. Recut 1 to 2 inches OFF the tip of the return line

and ensure the end is squared. Press the return

line tubing on completely past the barbs.

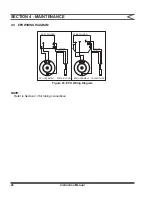

INCORRECT

CORRECT

Note gap between Flange

and Retaining Nut

No gap between Flange

and Retaining Nut

Figure 19. FASTPRIME™ Valve Assembly O-Ring Replacement

SECTION 4 - MAINTENANCE

Summary of Contents for ROYTRONIC A Series

Page 35: ......