www.lkarmatur.se | www.lkarmatur.com | www.lkarmatur.de

ENG

| Instruction Manual

1

LK 810 ThermoMat 2.0 G

TECHNICAL DATA

Voltage

230 VAC 50 Hz

Power consumption

5-52 W, depending on pump speed

Max. boiler efficiency

65 kW at 20 °C ΔT

Return temperature

55 °C, 60 °C, 65 °C or 70 °C

Working temperature

Min. 5 °C/Max. 110 °C

Ambient temp.

Min. 0 °C/Max. 70 °C

Max. working pressure 0.6 MPa (6 bar)

Media

Water - Glycol mixture max. 50%

Thread standard

Rp - female thread

Circulating pumps

Grundfos UPM3 AUTO L xx-70

Material, valve body

Brass EN 1982 CB753S

Material, insulation

Expanded Polypropylene EPP

LK 810 ThermoMat 2.0 G is a loading unit for heating applications

with solid fuel boilers and storage tanks. The loading unit is in-

tended to ensure a high return temperature as well as an optimal

temperature stratification in the storage tank, thus increasing the

efficiency of the system. Tarring and condensation are prevented

which prolongs boiler life.

CIRCULATING PUMP

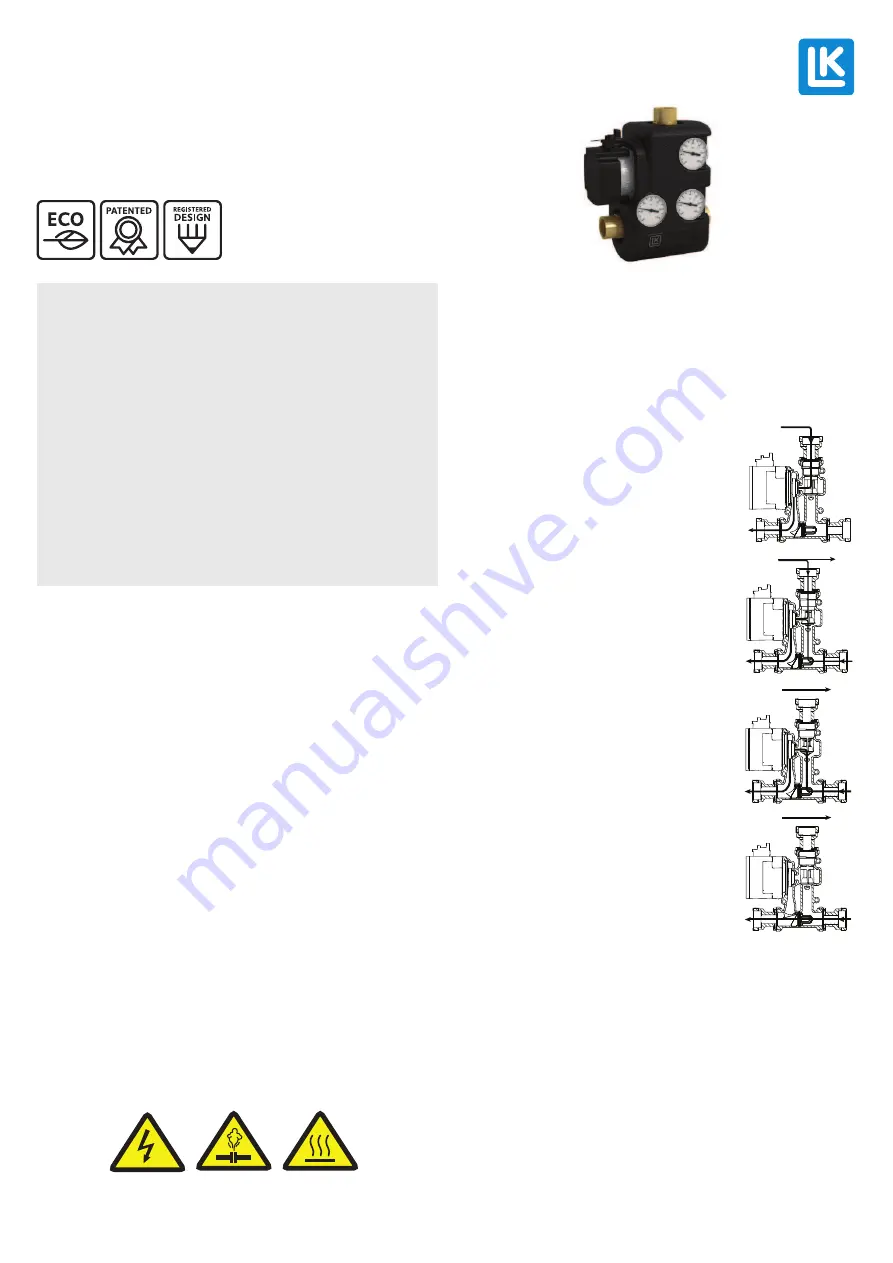

Four pump positions are available depending on boiler capacity.

It is to be noted that the maximum capacity of a boiler may be

higher than its nominal capacity.

FUNCTION OF THE BACKFLOW PREVENTER

LK 810 ThermoMat 2.0 G Eco loading unit has, depending on

model, a backflow preventer which automatically opens for self-

circulation when the pump stops. The backflow preventer has the

following functions:

1.

After the fire has gone out and the circulating pump has stopped

the remaining hot water will selfcirculate to the storage tank.

2.

In case of power failure the hot water will self-circulate to the tank.

3.

It prevents backflow from storage tank to heating boiler.

The function of the backflow preventer can, if needed, be blocked.

The backflow preventer is then replaced by a plug LKA art.no: 187

022. See page 9, part 8.

MOUNTING

For a trouble free system the piping work must be done without air

pockets. If this is not possible the system must be fitted with air vents.

Several boilers have integrated thermostats for pump control. If

not, a flue gas thermostat must be installed. The circulation pump

should start at the same time as the firing. The pump should stop

soon after the fire has gone out to let the remaining hot water in

the boiler self-circulate to the storage tank.

PIPE DIMENSIONING BETWEEN HEATING BOILER AND STORAGE

TANK:

•

LK 810 ThermoMat 2.0 G Eco loading unit with Rp 1” ball valve.

For heating boilers up to 40 kW ….. DN 25

•

LK 810 ThermoMat 2.0 G Eco loading unit with 28 mm ball valves.

For heating boilers up to 40 kW …. CU 28

•

LK 810 ThermoMat 2.0 G Eco loading unit with Rp 1¼“ ball valves.

For heating boilers up to 65 kW …. DN 32

1. Heat up phase

The water circulates between boiler and lo-

ading unit while the temperature of the boiler

is rising.

2. Loading phase

The thermostatic element starts to open and

allows return water from the storage tank to

be mixed with supply water before it returns

to the boiler. The return temperature to the

boiler is kept constant.

3. End phase

The thermostatic element is fully open and

the bypass is closed. This results in an opti-

mal transfer of heat from the boiler and the

storage tank is filled with supply water.

4. Self-circulation with check valve

Self-circulation will be obtained as soon as the

fire has gone out and the circulating pump has

stopped. The remaining hot water is loaded to the

storage tank. In case of power failure or pump

breakdown the check valve automatically opens to

allow self-circulation. The check valve also stops

recirculation from storage tank to boiler.

THE FUNCTION OF THE LOADING UNIT DURING THE DIFFERENT

PHASES OF HEATING: