TROUBLESHOOTING & REPAIR

F-13

F-13

SQUARE WAVE TIG 355

TROUBLESHOOTING GUIDE

Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.

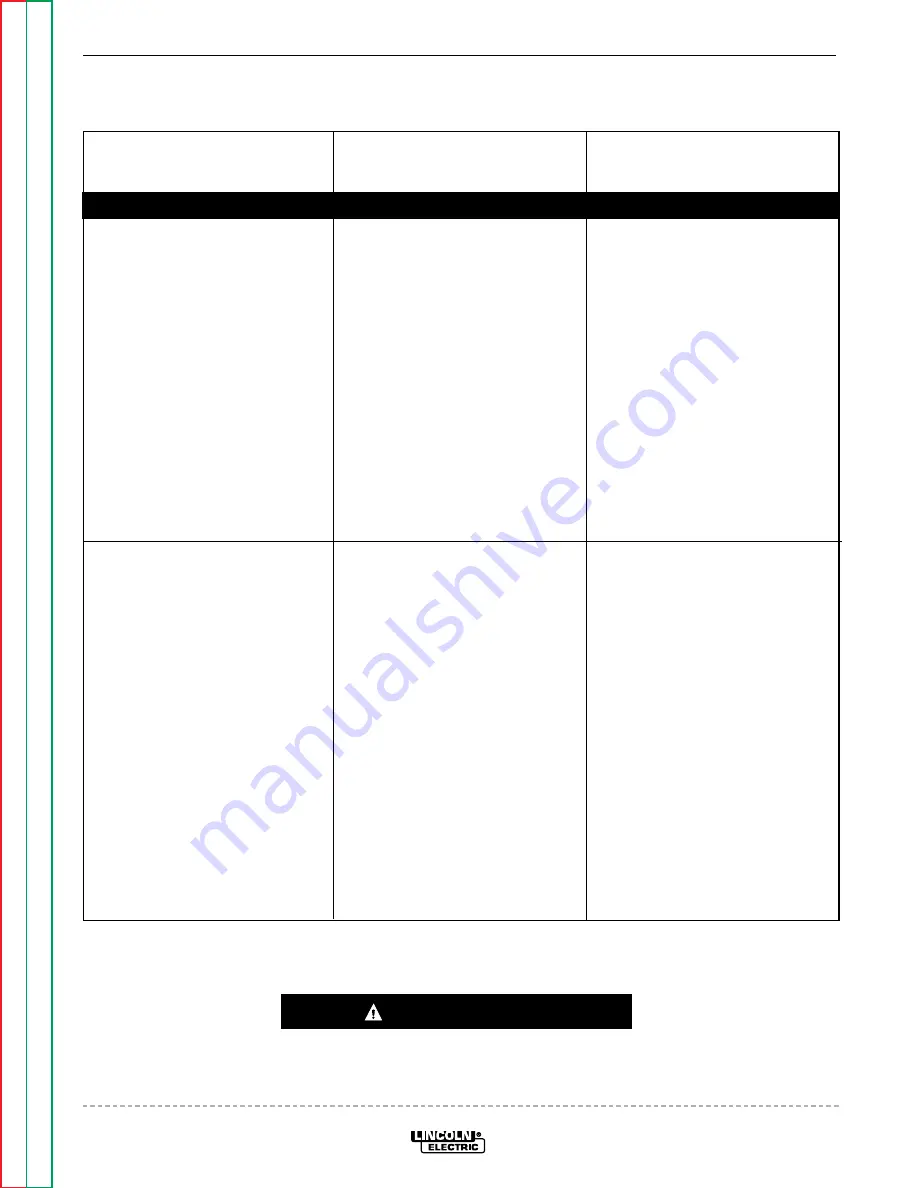

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

TIG MODE PROBLEMS

Weak high frequency – machine

has normal welding output.

1. The spark gap may be misad-

justed. Check and reset per

maintenance instructions.

2. Improper shielding gas flow.

Adjust for a flow of 10 to 30

CFH (4.7 to 14.1 l/min.) for

most applications.

3. Work and electrode cables

may be in poor condition,

allowing the high frequency to

“leak off.” Use good quality

cables with a high natural rub-

ber content, such as Lincoln

Stable Arc Cable. Cables

should be as short as possible.

1. Make sure that 115VAC is

being applied to the primary of

the high voltage transformer

(T3). See Wiring Diagram.

2. Check for an open or arcing

high frequency component.

Replace as required.

(Examples: R6, C6, C3, R4)

3. If spark is weak at the spark

gap, check or replace the high

frequency circuit. (Examples:

T3, L4, L5).

Lack of penetration in AC TIG

welding.

1. The AC Wave Balance control

may be set improperly – set-

tings above 3 give increased

penetration.

1. Check the AC Wave Balance

control potentiometer (R12) for

correct resistance and proper

operation. See Wiring

Diagram.

2. Check leads #443 and #444

for continuity from the AC

Wave Balance control poten-

tiometer to the lower control

panel. See Wiring Diagram.

3. Perform the SCR Rectifier

Bridge Tests.

4. The control board may be

faulty. Replace.

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC