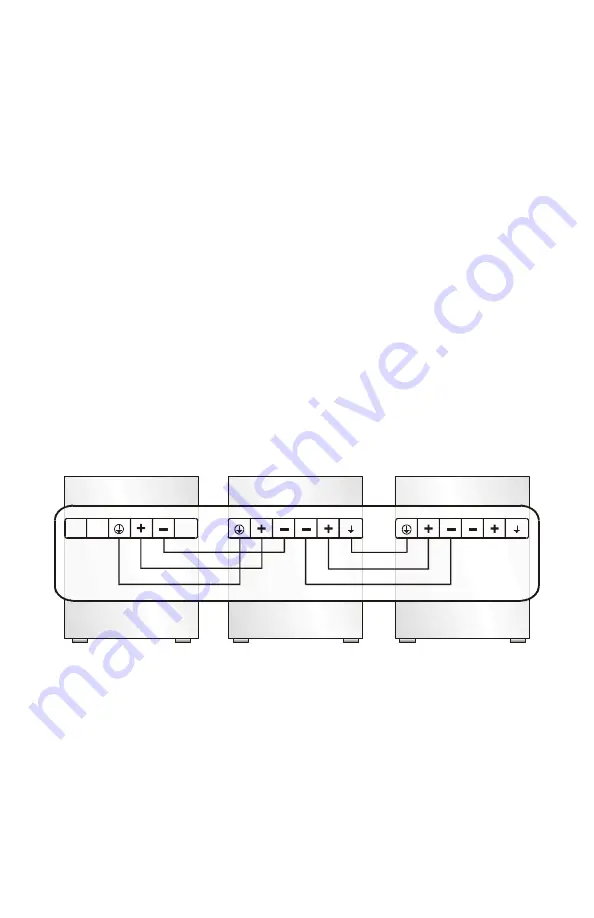

ELECTRICAL CONNECTIONS

The UPS and battery cabinets are supplied with battery terminals on the rear of

the UPS within a cable box. (see outline drawing) The cable box (gland plate)

can be removed to enable knockouts to be removed, or new holes drilled, to

secure the cables.

The cable sizes and distribution methods used during installation are subject to

local/national electrical codes of practice, and therefore are not detailed here.

Refer to the tables and wiring diagram in the UPS manual for your specific

model. Information is also provided on the battery cabinet rating plate. Rigid or

flexible conduit is recommended for all battery wiring.

The battery cabinet terminals will accept wire sizes up to the values below:

GXT6000 = 10 mm

2

(8 AWG)

Recommended for all GXT6000 wiring.

GXT10000 = 16 mm

2

(6 AWG)

Recommended for all GXT10000 wiring.

(75º C copper wire)

Terminal tightening torque is 40 cm-kg (35 in-lb).

In no case should the voltage drop on the battery cables exceed 2.0 volts at the

battery cabinet’s rated load.

Properly grounded (earthed) equipment provide multiple benefits.

High quality ground (earth) connections are required for the equipment ground

conductors (protective earth) and grounding electrode conductor (power system

earth connection) to reduce electrical noise and provide for safe operation of the

UPS and connected loads. Conduit used alone without a grounding conductor

wire is not an acceptable connection. Size ground (protective earth) conductors

equal to circuit conductors.

GXT 6&10 kVA

GXT 6&10

Battery Cabinets