User Manual for BPS-200

www.levitronix.com

PL-4012-00, Rev07, DCO# 20-144

16

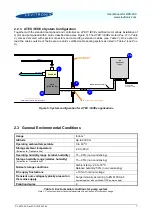

3.5 Hydraulic Circuit Design

Following general design rules for the hydraulic circuit shall be considered for a robust operation of the pump

system and optimum priming behavior:

1.

The general rule for optimum priming behavior is to minimize the pressure drop in the inlet circuit and

avoid negative pressure at the inlet of the pump head.

2.

Minimize tubing length at the inlet of the pump head and maximize the ID (not smaller than the pump head

inlet ID of 9.5 mm is recommended). This reduces the pressure drop and the tendency of cavitation.

3.

Avoid any restrictions, valves, elbows, bended tubing and sharp edges at the inlet circuit of the pump

head, which potentially causes cavitation resulting in gas bubble collection in the pump head with the

danger of priming loss.

4.

Place the pump at the lowest point of the hydraulic circuit. Optimum is as much as possible below a tank or

reservoir. This optimizes priming behavior and removal of gas bubbles.

5.

Keep the liquid level in the reservoir tank or bag as high as possible, which increases the inlet pressure of

the pump head and minimized heat up of the liquid.

6.

In general the pump system placement and circuit shall be designed in a way that gas bubbles can leave

the pump housing and that the pump head remains primed.

7.

To minimize heat up of the liquid the overall pressure drop in the hydraulic circuit shall be reduced as

much as possible.

8.

It shall be avoided to pump longer times against a closed valve, which can cause heat-up of the liquid.

9.

At flows < 1 l/min it is recommended to use a bypass loop to assure that sufficient flow runs through the

pump head to wash-out gas bubbles.

10.

There are specific pump heads, which are optimized for better priming and bubble robustness behavior

and others, which are optimized for higher viscosity and density. Select the suitable one according to

11.

At higher liquid temperature above rules become more important due to higher cavitation tendency of the

liquid.

12.

Load and stress at the inlet and outlet by heavy tubing and inexact mounting alignment shall be avoided

(see

) as this can cause leakage issues due to distortion of the plastic pump housing.

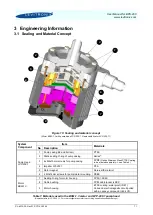

Figure 19: Avoidance of stress forces and torques at the inlet and outlet of the pump head

Contact the

Levitronix

®

Technical Service

department (see

Section 8

) for more detailed considerations and

support on the design of the hydraulic circuit.

Force/torque stress

at the in- and outlet

of the pump housing!

Tubing fixation/support to avoid

load at in- and outlet of pump system.

Pump

Heavy tubing at

in- and outlet of pump