Page 84

Job Editor

Group 8

Release 2.02

JET3 Series

6.7 Optional equipment

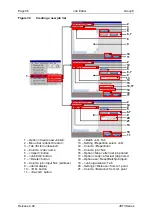

6.7.1 External head print ventilation - assembly and function

Function:

External head ventilation is predominantly used for devices in safety class IP65 and for

print jobs in which the retractive suction of particles (e.g. paper lint in the printing industry)

in printer circulations should be avoided.

For this purpose, the unit is provided with a

head ventilation

and a

housing ventilation

:

Head ventilation:

The printer's print head is impinged on with a constant air flow of

30l/h and thus the retractive suction of particles is prevented.

Housing ventilation:

With devices of protection class IP65, a great deal of heat is

generated due to the tight design of the housing. Due to this heat generation in

conjunction with the evaporation of the operating materials, an explosion danger zone

(Ex zone) can arise.

To prevent this, the interior space of the hydraulic housing is impinged on with a

constant air flow of 120 l/h and vented via a concealed drilled hole.

Assembly:

1. Outside of the rear panel of the housing:

The unit's pressure regulator valve is attached to the outside.

2. Inside of the rear wall of the housing:

Both of the throttle valves for the writing head ventilation and the housing ventilation

are attached to the inside. These valves are adjusted exactly as well as sealed and

may

not

be adjusted!

CAUTION

–

INSTALLATION OF PRINT HEAD

Both of the throttle valves are adjusted exactly and may not be adjusted!

ATTENTION

Make sure that there is a permanent compressed air supply!

The printer doesn’t monitor the permanent

compressed air

supply!

There will be no warning in case the permanent compressed air

supply fails!

Operation is only permissible with dry, oil-free and filtered

compressed air (Filtering 8

m) The use of otherwise prepared

compressed air can lead to damage and malfunctions!

Summary of Contents for JET3

Page 1: ...Operating Manual V2 02 Please keep for future reference ...

Page 2: ......