CS-D403 Closed Loop Stepper Drive User Manual

Page | 4

3. Connections and LED Indication

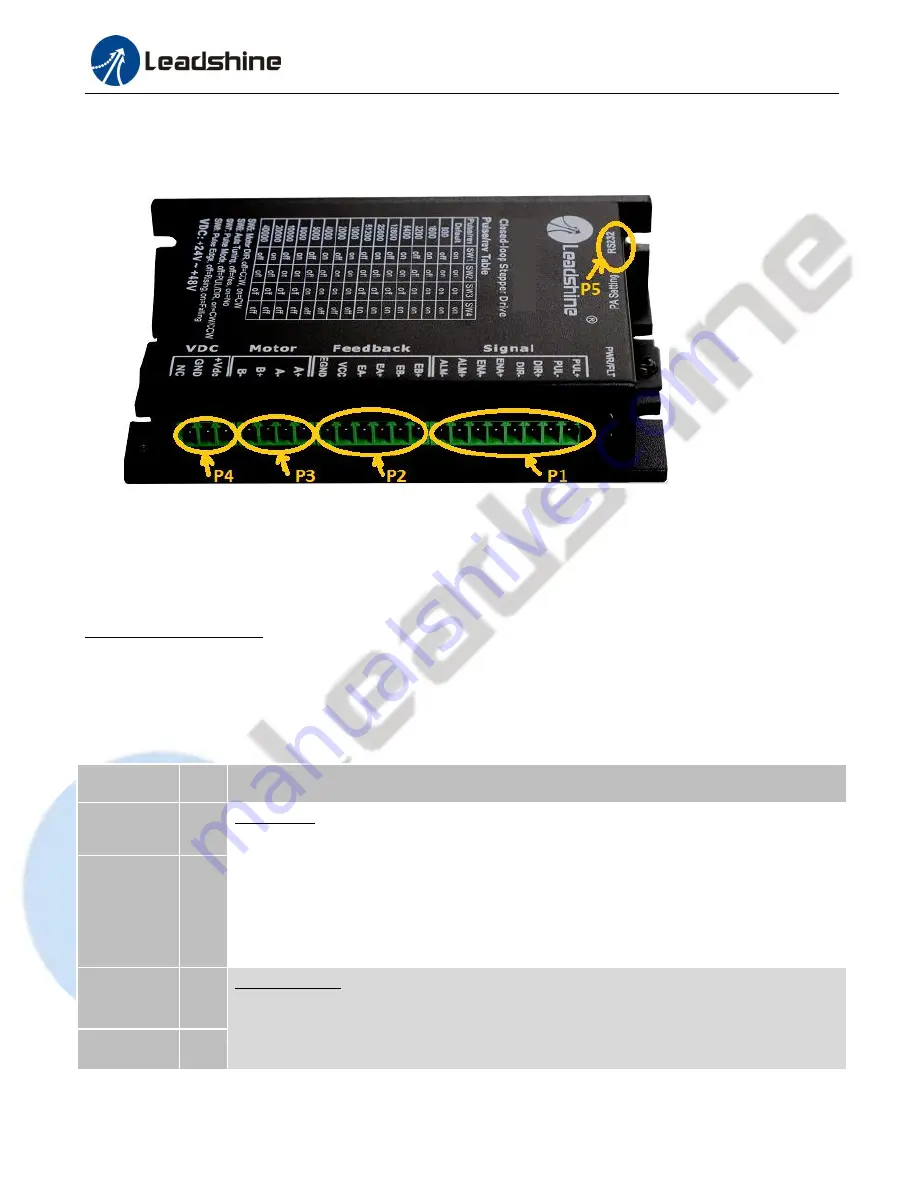

A CS-D403 closed loop stepper drive has 5 connection blocks from P1 to P5 (see figure 2).

Figure 2: CS-D403 connectors

3.1 Connector P1 – Control and Digital Output Connections

3.1.1 Pin Assignments of P1

The P1 connector in Figure 2 contains connections for control signals and a configurable digital output.

a) Pinout Definitions

There are 3 control signals for pulse, direction, and enable. See the following table for details.

Pin Name

I/O

Details

PUL+

I

Pulse signal:

(1)

. In single pulse (pulse & direction) control mode, this input represents pulse

signal. A pulse signal is active at the rising or falling voltage edge (set by DIP switch SW8).

(2).

In double-pulse (CW/CCW) control mode (set by DIP switch SW7), this signal input

represents clockwise (CW) pulse, and is active at both high voltage level and low voltage level.

(3).

4.5-5V for voltage HIGH, 0-0.5V for voltage LOW (same for DIR signals).

(4).

Pulse

width should be set to 2.5μs or longer.

PUL-

I

DIR+

I

Direction signal:

(1).

In single pulse (step & direction) control mode, this signal’s low and high

voltage levels represent the two directions of motor rotation (e.g. clockwise and

counterclockwise).

(2).

In double-pulse (CW & CCW) control mode, this signal represents

counterclockwise (CCW) rotation. It is active at both voltage high level and low level.

(3).

DIR-

I