CS-D1008E Closed Loop Stepper Drive User Manual

Page | 9

5.1 Regulated or Unregulated Power Supply

The CS-D1008E can power medium and large size stepping motors (frame size from NEMA 23 to 34). To get good

driving performances, it is important to select supply voltage and output current properly. Generally speaking, supply

voltage determines the high speed performance of the motor, while output current determines the output torque of the

driven motor (particularly at lower speed). Higher supply voltage will allow higher motor speed to be achieved, at the

price of more noise and heating. If the motion speed requirement is low, it’s better to use lower supply voltage to

decrease noise, heating and improve reliability.

5.2 Power Supply Sharing

Multiple CS-D1008E drives can share one power supply to save space and reduce cost, if that power supply has

enough power capacity. To avoid cross interference, connect each stepper drive directly to the shared power supply

separately. To avoid cross interference, DO NOT daisy-chain connect the power supply input pins of the Drivers.

Instead connect them to power supply separately.

5.3 Selecting Supply Voltage

The CS-D1008E is designed to operate within 18-80VAC or 24-110 VDC voltage input. When selecting a power

supply, besides voltage from the power supply power line voltage fluctuation and back EMF voltage generated during

motor deceleration needs also to be taken into account. Ideally it is suggested to use a power supply with the output of

30-90VDC or 20-70VAC, leaving room for power line voltage fluctuation and back-EMF.

If using an AC transformer,

be sure to use a transformer with isolation. Otherwise there is a risk of electrocution.

6. DIP Switch Configurations

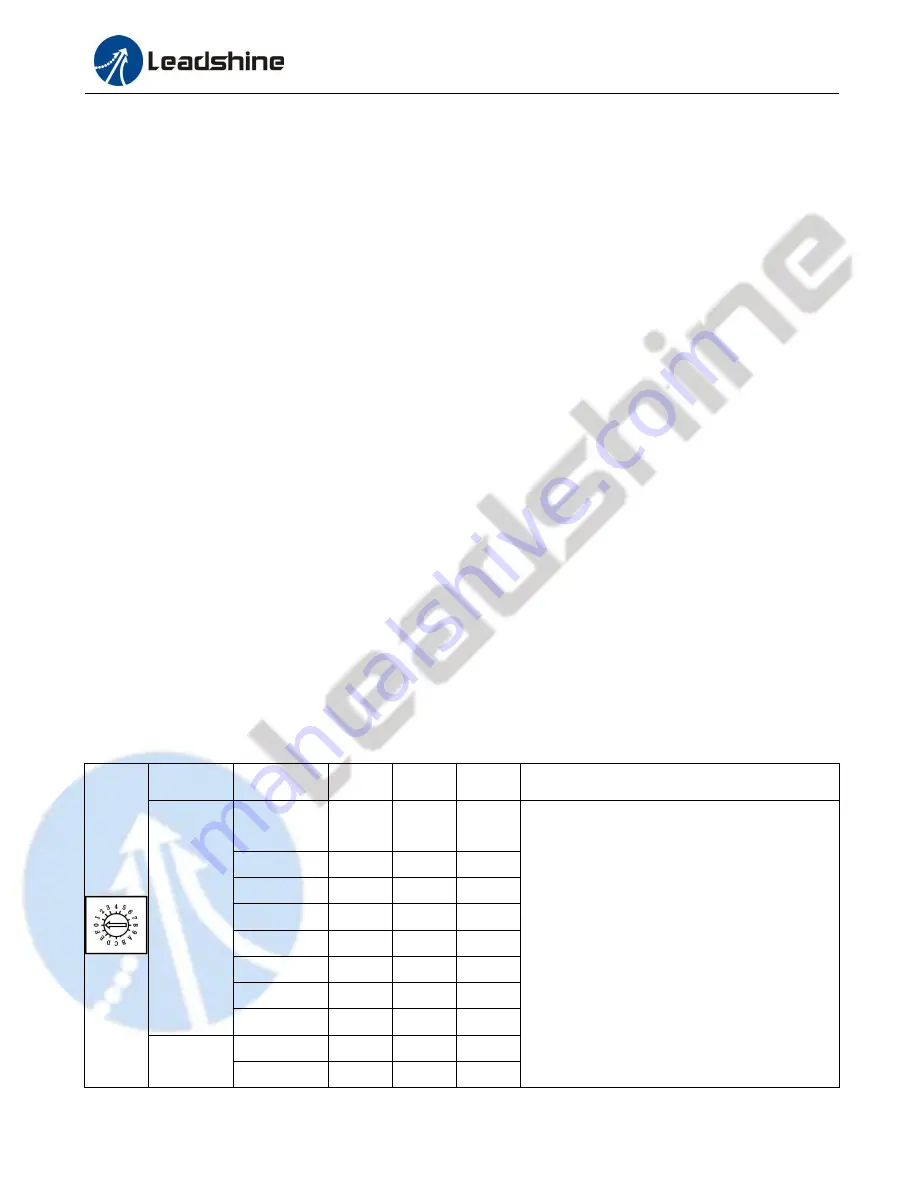

6.1 S1 - Rotating Switch Configurations

This rotating switch is used to set the peak current of the drive and motion gain, from the motor phase current and

application requirements.

Peak

Current

Code

Velocity

loop Ki

Position

loop Kp

Velocity

loop Kp

Remark

8.0 A

(Actual

output

current

fluctuates

from 4-8A

following

the load)

0 (factory and

default)

0

25

25

1) Velocity loop Ki indicates the stop time and

position accuracy, “0” indicates the stop time is

short, but the position error is slightly larger. “16”

means the stop time is long, but the position error

is smaller. As usual “0” meets most applications.

2) Position loop Kp and velocity loop Kp is a pair

of composite parameters that represent stiffness.

“25” and “25” composite parameters indicate the

stiffness is weak, “100” and “5” composite

parameters indicate the rigidity is strong.

Sometimes if the motor will rotate after stopping,

it can increase the value of position loop Kp, but

if the value is too large, the motor will have noise.

1

0

50

15

2

0

75

10

3

0

100

5

4

16

25

25

5

16

50

15

6

16

75

10

7

16

100

5

6.0 A

(Actual

8

0

25

25

9

0

50

15