5.

Fit the installation guide over the cam

splines so the 1/2" pin slots face the air

chamber.

6.

Swing the guide into the clevis until the

appropriate slot totally engages 1/2" pin.

7.

Observe the guide pointer arrow:

If the guide pointer is above the clevis

pointer, adjust clevis CCW for alignment.

If the guide pointer is below the clevis

pointer, adjust clevis CW for alignment.

8.

Reposition clevis until the guide pointer

aligns with the clevis pointer.

9.

Verify by engaging 1/4" pin through the

clevis and guide.

10.

Tighten jam nut to 50 ft.-lbs. torque min.

11.

Remove the guide from cam shaft.

12.

If the push rod threads extend through the

clevis more than 1/16", remove clevis and

cut rod to length.

13.

If the push rod is not fully engaged in

clevis body, install a new push rod - cut to

length.

14.

Install the slack adjuster on the cam shaft.

15.

Rotate the manual adjuster shaft CW until

the slack adjuster arm holes align with the

clevis. Install 1/2" and 1/4" pins and cotter

pins.

c. Adjusting Slack Adjuster

1.

Rotate the manual adjuster clockwise until

brake shoes contact drum.

2.

Back off manual adjuster 1/2 turn.

(counterclockwise)

3.

Manually uncage the spring brake.

4.

Build up vehicle air pressure.

5.

Fully apply and release the brakes several

times to check for adequate clearance to all

adjacent components.

6.

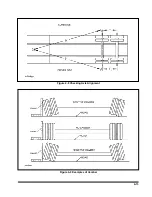

Measure the distance from air chamber to

1/2" pin. Apply brakes with 100-105 psi air

pressure and remeasure distance to 1/2"

pins.

7.

The stroke (difference of these two

measurements) must be less than 2 inches.

4-20

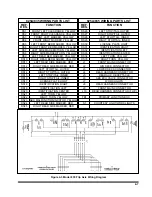

Figure 4-13 Slack Adjuster

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......