3-21 ANTI-LOCK BRAKE SYSTEM (ABS)

Vehicle standards FMVSS No. 121, anti-lock

brake system requires all trailers manufactured af-

ter March 1, 1998 with air brake systems to have

ABS. Each trailer (including a trailer converter

dolly) shall be equipped with an anti-lock brake

system that controls the wheels of at least one

axle of the trailer. Wheels on other axles of the

trailer may be indirectly controlled by the anti-lock

brake system.

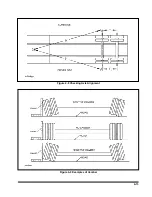

NHTSA Docket 92-29; notice 11 published

September 23, 1996 specifies the ABS warning

light be mounted near the rear of the left side of

the trailer

(See Figure 3-1)

.

·

Decal or lens marking with ABS to identify

the lamp.

·

The lamp must illuminate one time whenever

power is supplied to the ABS. At any time

the light remains on when power is supplied

there is a malfunction to the system.

The ABS used on the semitrailer is a commer-

cial unit. Single axle trailers use a two sensor, one

modulator system. Tandem axle semitrailers use a

four sensor, two modulator system. Sensors are lo-

cated at each hub of the front and rear axles, and

each modulator controls one side of the trailer.

The ABS is constant powered by the auxiliary

(blue) circuit, center pin on the semitrailer seven

way electrical connector. This circuit must be hot

whenever the tractor keyswitch is on. This circuit

must also not be used to power any additional

electrical devices while the semitrailer is moving

forward. However, additional devices such as re-

mote controls may be powered from the auxiliary

circuit while the semitrailer is stationary. Back up

power to the ABS is supplied through the stop

lamp (red) circuit, No. 4 pin on the seven way con-

nector, and ground is supplied by the white wire,

No. 1 pin.

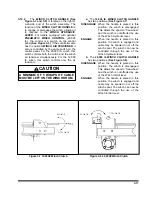

CAUTION

THE AUXILIARY (BLUE) CIRCUIT IS

FOR POWERING THE SEMITRAILER

ABS. THIS CIRCUIT MUST BE HOT

WHEN THE TRACTOR KEY SWITCH IS

ON. NO OTHER ELECTRICAL DEVICES

MAY BE POWERED BY THIS CIRCUIT

WHILE THE SEMITRAILER IS MOVING

FORWARD.

Malfunction in the ABS is signaled by illumina-

tion of the ABS warning lamp located at the left

rear side of the semitrailer. The warning lamp will

come on and stay on while power is supplied to

the ABS on a moving vehicle, if there is a fault. If a

fault in the ABS exists, normal braking will still oc-

cur, but wheels may lock. The semitrailer is still op-

erable, but the system should be serviced as soon

as possible.

CAUTION

IF A FAULT EXISTS IN THE SEMI-

TRAILER ABS, NORMAL BRAKING

WILL OCCUR, BUT WHEELS MAY

LOCK. SERVICE THE ABS AS SOON

AS POSSIBLE.

The ABS is also equipped with a Blink Code

Diagnostic Tool mounted at the right rear corner of

the trailer

(See Figure 3-1)

. This tool is used to

identify faults that may occur in the ABS so that

they may be repaired.

Refer to ABS maintenance manual supplied

with semitrailer to answer basic questions for the

anti-lock brake system, obtain outline procedures

on how to adjust, test, remove, and install ABS

components, as well as how to test for faults in the

system by using “Blink Code Diagnostics”; and il-

lustrates ABS components, wiring, and plumbing

installation diagrams.

3-20

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

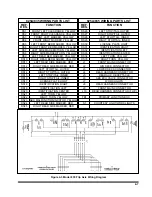

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......