4-12 WINCHES

Inspect the winch cable before and after

every

usage. If frayed wires, nicks, kinks, worn spots,

breaks or any other sign of deterioration or dam-

age is found, immediate replacement is mandatory

before further usage. If the semitrailer is going to

be out in the weather for any length of time, it is

advisable to oil the winch cable to prevent untimely

rusting and deterioration of the cable. See

Table

for lubrication specifications.

Inspect the winch mechanism thoroughly each

week to insure safe, efficient operation.

WARNING

DO NOT HANDLE THE WINCH CABLE

WHEN THE WINCH IS IN THE ENGAGE

POSITION. HANDS OR CLOTHING

COULD GET CAUGHT IN THE CABLE

AND BE PULLED INTO THE SPOOL

CAUSING SERIOUS PERSONAL IN-

JURY.

4-13 DOCK LEVELERS

4-13.1

Perform the following service procedure

on a yearly basis:

a.

Change oil with legs fully extended.

b.

After oil change, operate the dock leveler at

least three full cycles (complete leg strokes)

to bleed air from system.

c.

Fully extend legs. Clean extended legs.

Coat lightly with clean grease and grease ale-

mite fitting on each leg and check valve.

d.

Check all hydraulic lines and fittings for

leaks and worn spots. Replace any defective

lines and fittings.

e.

Check for loose bolts and nuts.

4-13.2

Disassembly/Assembly Procedure

When disassembling and reassembling the leg,

care should be taken to keep all parts clean and to

prevent parts from being damaged. All seals

should be coated lightly with grease before reas-

sembling the leg.

4-13.3

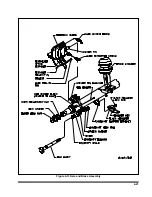

Lock Valve (See Figure 4-21)

a.

Remove retaining plug.

b.

Remove o-ring plug opposite retaining plug

on rectangular block.

c.

Using a drift small enough to fit through the

port opened in the previous step, tap out the

lock valve cartridges.

d.

Install new lock valve cartridges back to

back (as illustrated). Grease o-rings.

e.

Install two new o-rings and two back-up

washers on retaining plug.

f.

Thread retaining plug into body (tap gently

to engage threads). Torque plug to 15 ft.lbs.

g.

Install new o-ring on plug, opposite retaining

plug. Thread plug into body. Torque to 70

in.lbs.

h.

Replace spring and poppet. Replace the o-

ring on plug and reinstall.

i.

Install new o-rings and back-up washers on

top of piston rod.

j.

Thread lock valve on piston rod until firmly

seated. If the ports need to be relocated,

loosen the screw at the top of the well tube

and turn lock valve clockwise until ports are at

the desired location. Retighten the set screw.

4-30

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...