IMPORTANT

TO CHECK THE TENSION ON THE LATCH,

PLACE A PRY BAR BETWEEN THE FIFTH

WHEEL PLATE AND THE BACKING PLATE

AND PRY DOWN UNTIL THE LATCH RE-

LEASES. IF IT RELEASES TOO EASILY,

TIGHTEN THE SPRING TENSION. IF YOU ARE

UNABLE TO TRIP IT, BACK OFF THE SPRING

TENSION UNTIL YOU ARE ABLE TO TRIP THE

RELEASE.

WARNING

1. TOO MUCH TENSION WILL CAUSE

EXCESSIVE WEAR ON THE RELEASE

AND POSSIBLY BEND THE LATCH

ROD.

2. STAND CLEAR OF FIFTH WHEEL

PLATE WHEN PRYING IT DOWN. FAL-

LING PLATE COULD CAUSE SERIOUS

INJURY.

4-4 HYDRAULIC SYSTEM

4-4.1

General

a.

Check the oil level of the tractor wet kit or

hydraulic engine power hydraulic tank weekly,

or after any leakage. See

Table 4-1

for proper

hydraulic oil. Check the hydraulic oil level with

hydraulic cylinders in the retracted position

and the hydraulic pump disengaged. Enough

volume in tank (approximately 15 gallons)

above hydraulic oil level must be available to

accept extra oil from telescopic cylinder when

retracted.

b.

Overfilling can cause hydraulic fluid overflow

during operation.

c.

Dock leveler flow bypass regulator must

provide 2.5 to 3.0 gallon per minute to dock

leveler valve for Single Pair Dock Leveler

(62,000 lb.). Dock leveler flow bypass regula-

tor must provide 6.0 gallon per minute to dock

leveler valve for Double Pair Dock Leveler

(124,000 lb.).

d.

Hydraulic system pressure relief valves

should be set at 2500 psi.

4-4.2

Hydraulic Engine Package

a.

Check the hydraulic oil level weekly, or after

any leakage. See

Table 4-1

for proper hy-

draulic oil. Check oil level with the undercar-

riage telescopic cylinder extended and all

other hydraulic cylinders in the retracted posi-

tion and with the engine stopped.

b.

Check hoses weekly for cracks or leaks. If a

valve or line leaks, it should be replaced im-

mediately.

c.

Check the engine oil each time before us-

ing. Oil level should be maintained between

the “L” and “F” marks on the oil dip stick. For

further maintenance procedures and proper

lubrication specifications, please refer to the

engine owners manual that was supplied with

the hydraulic engine package.

d.

Replace hydraulic filter with new filter at

least every 2000 hours or more often under

adverse conditions.

e.

Use the fuel recommended for the engine

package installed on your semitrailer.

WARNING

IF MORE OIL THAN SPECIFIED IS

SENT TO DOCK LEVELER VALVE,

DAMAGE TO DOCK LEVELERS AND

PERSONAL INJURY CAN OCCUR. IT

LESS OIL THAN SPECIFIED IS SENT

TO DOCK LEVELER, THEY WILL NOT

OPERATE OR OPERATION WILL BE

ERRATIC.

4-7

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

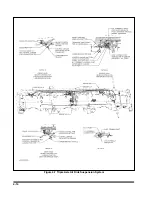

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

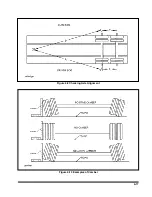

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

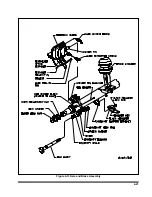

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...