Page 42

Causes and remedy of faults

Signal on site

Fault

Cause

Remedy

Green LED

"Operating voltage /

Spänning"

(

19

) does not illuminate

and

display of the

ACS

(

18

) is dark.

Equipment does not receive operating

voltage.

Operating voltage is not switched on.

Faulty wiring.

Power plug is not fitted correctly.

24 V (

26

) power pack is defective.

Switch on operating voltage.

Check wiring,

retighten terminal screws.

Check power plug.

Replace power pack.

Green LED

"Operating voltage /

Spänning"

(

19

) does not illuminate

Green LED „DC OK” in 24 V (

26

) power

pack does not illuminate.

24 V (

26

) power pack does not receive

operating voltage.

24 V (

26

) power pack is defective.

Green LED "Operating voltage / Spän-

ning" (

19

) is faulty.

Check wiring, retighten terminal

screws at power pack.

Replace power pack.

Replace LED.

Display of ACS (

18

) is dark.

ACS (

18

) does not work.

Screensaver is active.

Faulty wiring,

or

2 4 V (

26

) power pack

does not receive operating voltage.

24 V (

26

) power pack is defective.

Microfuse „DC” (

B

) at MFR (

45

) is

defective.

ACS is defective.

Press any key of the ACS.

Check wiring, retighten terminal

screws at power pack.

Replace power pack.

Replace microfuse:

type M 2.0 A

Replace ACS.

Red signal-LED „

Fault / Fel“

(

20

) on

the instrument panel (

2

) illuminates.

Red Signal-LED „

F“

(

48

) on the MFR

(

45

)

illuminates

.

Humidity fault = relative humidity of

output air is unadmissibly high.

Maintenance of air dryers (

35

) was not

carried out.

Pressure limiting valve (

38

) is set

incorrectly or defective.

Double non-return valve (

39

) is defec-

tive.

Condensate discharge hose (

10

) is bent

or blocked, its diffusor is clogged.

Electric triggering of solenoid valves

(

36

) of air dryers (

35

) fails or is in

wrong clock pulse.

Solenoid valves (

25

) are defective or

worn out.

Carry out maintenance of air dryer, see

page 40.

Set pressure limiting valve properly,

see page 33, replace if necessary.

Check amount of regeneration air (270 -

300 l/h), replace double non-return

valve (

39

) if necessary, see page 41.

Check hose, replace diffusor if neces-

sary.

Check cycle time, see page 31.

Watch relay KY1 u. KY2, check wiring

and plugs of solenoid valves.

Replace solenoid valves

Red signal-LED „

Fault / Fel“

(

20

) on

the instrument panel (

2

) illuminates.

Red Signal-LED „

F“

(

48

) on the MFR

(

45

)

flashes

.

Humidity sensor (

41

) of MFR is defec-

tive or wiring is defective.

Check wiring, replace humidity sensor

if necessary.

Red signal-LED „

Fault / Fel“

(

20

) on

the instrument panel (

2

) illuminates.

Red Signal-LED „

T-runtime“

(

53

) on

the MFR (

45

)

illuminates

.

Runtime alarm: compressors runs for a

longer time than preset (see page 31)

Equipment is permeable.

Pressure monitor (

40

) is defective or

set wrong.

Compressor safety valve (

23

) blows off.

Safety valve „high pressure” (

29

)

blows off.

Safety valve „cable pressure” (

24

)

blows off.

Solenoid valves (

36

) of air dryer (

35

) do

not close.

Double non-return valve (

39

) is con-

taminated or blocked.

Compressor ot compressor hose is

permeable.

Compressor output is insufficient.

Thermal protection in the coil of the

compressor motor has initiatied.

Compressor’s electrical connection is

faulty.

Check hoses for permeability.

Set pressure monitor or replace it (see

page 32).

Test opening pressure (7 bar, typical

value at ACS display is 5.7 - 6.1 bar)

and replace safety valve if necessary,

Check hoses for clogging.

Replace safety valve.

Set cable pressure (see page 30),

replace safety valve if necessary.

Check solenoid valves, replace them if

necessary.

Check amount of regeneration air (270 -

300 l/h), replace double non-return

valve if necessary, see page 41.

Seal/replace permeable parts of com-

pressor, hoses or connectors.

Replace air-intake filter or compressor

if necessary.

compressor overheating: check fan

(

27

) and aeration

Check compressor pressure

Replace compressor if its bearings are

worn or defective.

Check wiring, retighten terminal

screws.

Red signal-LED „

Fault / Fel“

(

20

) on

the instrument panel (

2

) illuminates.

Green Signal-LED „

AC“

(

50

) on the

MFR (

45

)

is dark

.

Microfuse „AC” (

A

) at MFR (

45

) is

defective.

Replace microfuse:

type M 0.315 A

Summary of Contents for RTS 1000

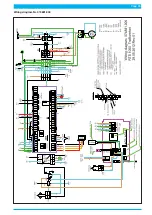

Page 15: ...Page 15 39 35 37 36 36 23 42 28 27 24 6 33 38 40 41 32 22 29 25 8...

Page 21: ...Page 21...

Page 47: ...Page 47 7 16 14 15 15 18 17 13 20 24 8 23 10 6 9 4 22 21 19 8...

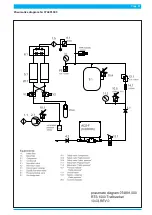

Page 51: ...Page 51 Pneumatics diagram Nr 074891 000...

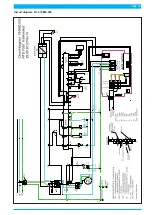

Page 53: ...Page 53 Circuit diagram Nr 074880 000...