16

Operating

Before using your Brush, review the previous pages in

this manual on initial set-up and adjustment. In this

section, you will learn how to operate the machine.

Note that connecting the machine to an adequate

dust collection system is necessary before operating

the unit.

The Brush offers considerable control and versatility

through variable brush speed and feed rate.

Experiment with both to find the proper sander

performance for a given application. Varying the

brush speed makes the brush more or less aggressive.

Too aggressive on the brush may tend to raise the

grain or excessively round edges. Sometimes it may

be better to make two or more passes with a less

aggressive brush or setting.

The brush is rotating against the direction of feed;

therefore, the leading edges of contours will receive

more sanding than trailing edges. Stock should be

reversed on subsequent passes to sand all surfaces.

Stock may also be fed at an angle to allow more brush

penetration on the sides.

Basic Operating Procedures

After you have connected the machine to a dust

collection system, you are ready to begin to use the

Brush. The basic operating procedure for the Brush

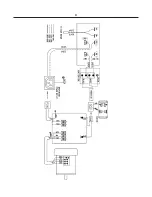

is as follows (Fig. 10):

1.

Set depth of cut/bristle contact (page 10).

2.

Set tension rollers to type of stock being

sanded (See Tension Roller Adjustment below

and Fig. 11).

Fig. 10 Operating controls.

3.

Start sanding brush and select slow brush

speed (page 8).

4.

Start conveyor and select feed rate (page 10)

5.

Start dust collector system.

6.

Feed stock through unit.

7.

Gradually increase brush speed (RPM) until

the desired finish is achieved (Fig. 8).

To feed stock through the SuperBrush, rest and

hold the stock to be sanded on the conveyor table,

allowing the conveyor belt to carry the stock into the

brush. Once the stock is halfway through, reposition

yourself to the outfeed side of the machine to receive

and control the stock as it exits the unit.

Tension Roller Adjustment

Spring loaded infeed and outfeed Tension Rollers (Fig.

11 & page 26) are provided to maintain downward

pressure on stock being sanded and to prevent slippage

of the stock on the conveyor. When properly set, the

Tension Rollers should engage or raise up about

1/8”

to accommodate the stock being brushed.

The Tension Rollers can and must be adjusted to

accommodate flat surfaced stock vs highly contoured

surface stock. Tension Roller height is adjusted as

follows: Note: Make sure brush head is appropriate

for application and contact.

Tension Roller Pressure

The tension roller pressure is factory set for most

applications. However, the pressure of each roller can

be adjusted. Caution, too little pressure can result in

slippage of stock on conveyor belt or kick-back. Too

much tension can cause snipe when drum sanding

or not enough lift when sanding profiled material.

To increase tension, turn the tension adjusting

screw clockwise ¼ revolution at a time. To decrease

tension, turn the adjusting screw counterclockwise ¼

revolution at a time. See fig (11).

Tension Roller Pressure

The tension rollers are factory set for the most versatile

use and longest minimum length, approximately

4-

1/2” for most applications.

The rollers can be

adjusted closer to the sanding drum when sanding

Summary of Contents for SuperMax 19-38 Combo

Page 1: ...19 38 Combo Brush Drum Sander Owner s Manual Lagunatools com SKU 219383...

Page 31: ...31...

Page 34: ...34 34...

Page 36: ...36...

Page 39: ...39...