INSTRUCTIONS OF USE

11

3.

INSTRUCTIONS OF USE

3.

The manufacturer accepts no liability

whatsoever for damage caused to parts as

a result of the improper use of non-

recommended fuels, modifications made

to the appliance or how it is installed.

Only use original replacement parts.

All local and national regulations,

including those referring to national and

European standards, must be observed

when using the appliance.

Heat is diffused by radiation and

convection via the front and exterior of the

appliance.

3.1.

Fuel

This appliance must not be used as an

incinerator. Do not use non-recommended

fuels.

Use dry logs (max. 16% humidity),

cut at least 2 years ago, clean of resin

and stored in a sheltered, ventilated

place.

Use hard woods with high calorie

values and good ember production.

Large logs should be cut to useable

lengths before being stored. The logs

should have a maximum diameter of

150mm.

Finely-chopped wood produces

greater heat output, but also burns

more quickly.

Optimum fuels:

Beech.

Other fuels:

Oak, chestnut, ash, maple, birch,

elm, etc.

Pine and eucalyptus logs are low

density and produce very long flames,

and may cause the parts of the

appliance to wear out more quickly than

normal.

Resinous wood may mean that the

appliance and the flue need to be

cleaned more often.

Non-permitted fuels:

All types of coal and liquid fuel.

or damp

wood reduces the performance of the

appliance and leads to soot and tar

build-up on the inner walls of the flue,

obstructing it.

treated woods (railway sleepers,

telegraph posts, plywood, fibreboard,

pallets, etc.) quickly blocks the system

(soot and tar build-up), harms the

environment (pollution, smells) and

may lead to deformation of the firebox

due to overheating.

All materials which are not wood

(plastic, spray cans, etc.).

Green and reprocessed wood may cause

chimney fires.

The graph below shows how the

humidity of firewood affects its heat

output:

Figure No.9 -

Relationship between firewood

humidity and heat output.

Summary of Contents for Sara

Page 1: ...Sara Lorea Abodi Andrea Instruction Book...

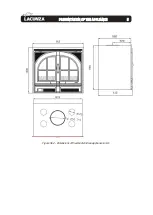

Page 6: ...PRESENTATION OF THE APPLIANCE 5 1 Figure No 2 Dimensions of the Abodi Andrea appliance in mm...

Page 19: ...BASIC BREAKDOWNS 18 6 BASIC BREAKDOWNS 6 NO TRADUCIR EL TEXTO DE ESTA IMAGEN...

Page 21: ...DECLARATION OF PERFORMANCE 20 7 DECLARATION OF PERFORMANCE 7...

Page 22: ...DECLARATION OF PERFORMANCE 21 7...

Page 23: ...DECLARATION OF PERFORMANCE 22 7...

Page 24: ...DECLARATION OF PERFORMANCE 23 7...

Page 25: ...CE MARK 24 8 CE MARK 8...

Page 26: ......