Chapter 6: Maintaining the Nano Enclosure

Product Service 1-800-522-7658

31

Filter Leak Test

Purpose

After installing the new ULPA filter, the filter should be leak checked. This test is

performed to determine the integrity of the ULPA filter, the filter housing, and the

filter mounting frames. Leak testing is to be done by a qualified technician with

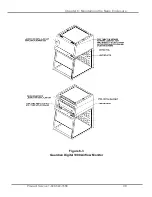

calibrated equipment. Remove the top perforated exhaust cover by using a Phillips

screwdriver to unfasten the (2) screws used to secure (2) clips. See Figure 6-1. The

filter passes the leak test at .01% or better. Reference Leak Testing and Photometer

scanning from the Institute of Environmental Services (IES-RP-CC001.3)

Apparatus

1.

An aerosol photometer ATI model 2D, 2E, 2G or equivalent

. Air

Techniques Hamilton Associates Inc., 11403 Cronridge Dr., Owings Mills,

MD 21117

2.

One aerosol generator of the Laskin nozzle(s) type

. An aerosol of mineral

oil or suitable liquid shall be created by flowing air through it. The compressed

air supplied to the generator should be adjusted to a pressure of 10± 1 psig

during operation. Air Techniques Inc. Model TDA-4A or equal. One nozzle at

10 psig is (67.5 cfm x 100ug/l)/(Vol. of air), For the 2' at 90 fpm or 130 cfm,

one nozzle @10 psig is 6,750/130 cfm = 52 ug/l. For the 3' at 90 fpm or 200

cfm, one nozzle @ 10 psig is 34 ug/l. For the 4' at 90 fpm or 265 cfm, one

nozzle at 10 psig is 26 ug/l. For the 5' at 90 fpm or 215 cfm, one nozzle at 10

psig is 31 ug/l. For the 6' at 90 fpm or 260 cfm, one nozzle at 10 psig is 26

ug/l. Note 5' and 6' use two filters.

3.

Mineral oil

(Catalog #1491400).

4.

Sampling Nozzle, Rectangular

1/2" x 3

-

1/4", Air Techniques, Inc.

Procedure

For the ATI 2G Photometer

1.

Turn on the photometer and allow it to operate for a minimum of 5 minutes.

Leave the valve in the “CLEAR” setting.

2.

Press the “ENTER” keypad. Press the “REF” keypad.

3.

The display will display “P1” for approximately 1 second, and then display a

numerical value.

4.

Using the “^” or “ν” keypads, respectively, increase or decrease the numerical

value until it equals 52 (2'), 34 (3'), 26 (4'), 31 (5'), 26 (6') for the enclosure at

90 fpm inflow velocity.

5.

Press the “ENTER” Keypad. The photometer will scan for 15 seconds, and

then the “0” keypad will flash. Press the “Enter” keypad. The unit will scan for

5 seconds, the display will read “0000,” and the unit will sound a confirming

tone.