LAARS Heating Systems

Page 16

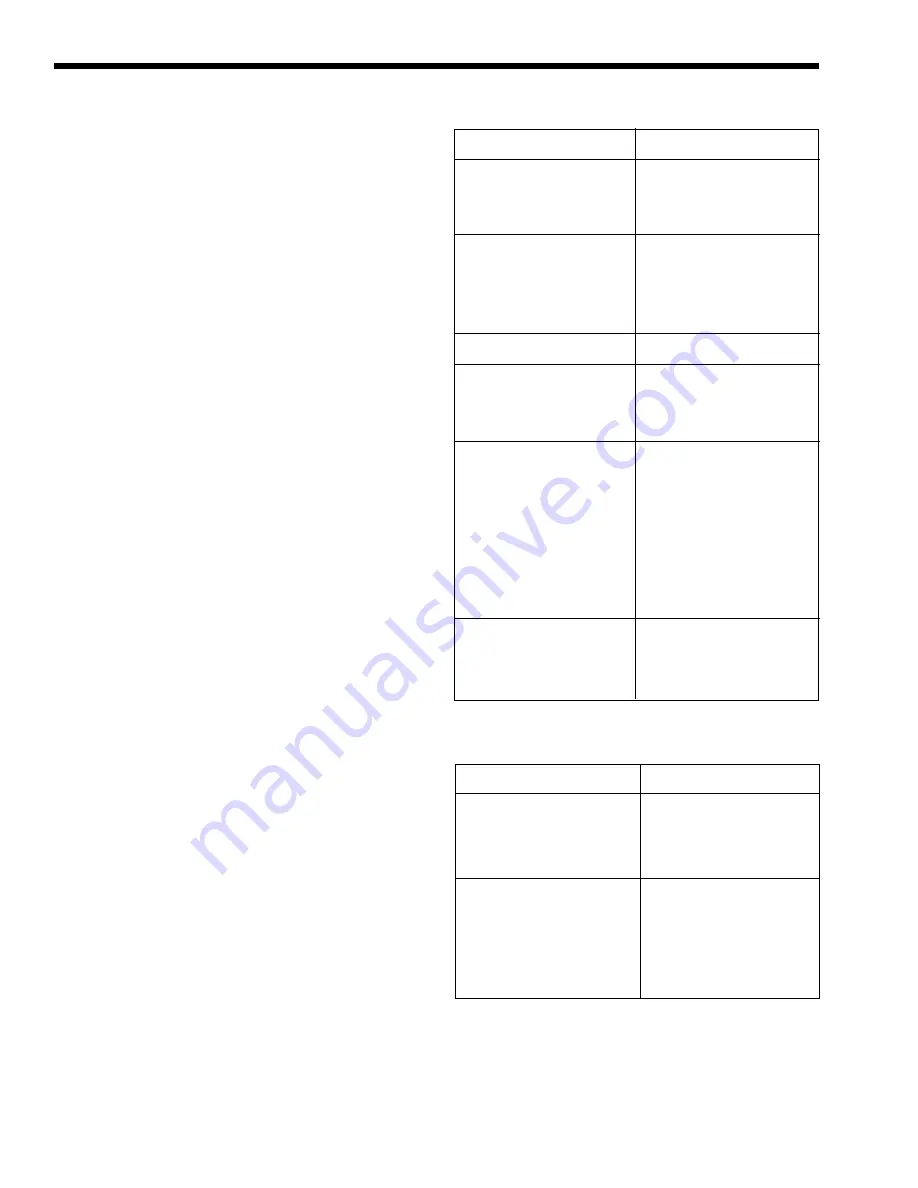

4. PRESSURE RELIEF VALVES LEAKING

INTERMITTENTLY OR STEADILY.

3. BOILER WILL NOT FIRE.

Possible Cause

What To Do

A. Electric power is off.

A. Check to see that main power

switch is “ON.” Use testing

device to trace power to

boiler junction box.

B. Operating or safety control has

B. Turn off power. Use continuity

opened circuit to electric

across terminals of each

gas valve.

operating and safety control

switch up to the electric gas

valve. Replace defective

control.

C. Pilot flame is out.

C. Relight pilot per instruction.

D. Manual reset device has tripped. D. Follow instructions for start-up.

Reset Pilot safety and all

manual reset safety switches

and reset manual safety gas

valve.

E. No gas pressure to burners.

E. Trace gas line to service shutoff

cock. If service cock is open,

trace gas line to meter. If no

pressure is present at meter,

call for public utility service. If

gas is present in boiler inlet,

check pressures in following

sequence: (1) downstream from

pressure regulator;

(2) downstream from electric gas

valve. Replace or adjust as

necessary.

F. Electric gas valve operator is

F. Disconnect wiring harness at gas

burned out or shortened.

valve terminals. Check continuity

to actuator coil. If open circuit or

short is indicated, replace coil or

operator.

Possible Cause

What To Do

A. Static pressure in system

A. Calculate height of water in

exceeds setting of relief valve.

system above boiler. Install new

valve with psi setting 25% above

required static system working

pressure. Do not exceed 160 psi.

B. Expansion tank is waterlogged

B. Drain expansion tank, then

(if installed).

reopen it to the system. Look for

leaks in expansion tank or

fittings. Calculate required

volume of expansion tank in

relation to system to determine

that tank is adequate.

SECTION 5.

Troubleshooting and Analysis of

Service Problems

1.

For proper service and problem diagnosis of the

heater and heater system, the following tools are

required:

a.

Gas pressure test kit with range from zero

to 14 W.C. Either a slack tub manometer or

an accurate gas pressure gauge is

acceptable with proper adapters which will

connect to the available fittings in the line

and on the gas valve.

b.

Multi-meter with the following ranges:

0 to 500 volts A.C.

0 to 1000 ohms continuity.

c.

Tube cleaning kit consisting of reamer,

stainless steel brush, speed handle and

handle extensions.

d.

Strap on digital temperature gauge to check

temperature rise.

2.

In addition, the boiler should be equipped with a

system pressure gauge with proper ranges for

boiler operation.