Mechanical safety

Mechanical safety

Flown congurations

The KARADOWNK2 rigging system complies with 2006/42/EC: Machinery Directive. It has been designed following

the guidelines of BGV-C1.

2006/42/EC: Machinery Directive species a safety factor of 4 against the rupture. The own deployments described in

this manual achieve a safety factor of

4

.

Refer to Soundvision for the safety factor of a specic deployment.

The

maximum limit

gives the maximum number of elements for which the safety factor can be compliant with the

2006/42/EC: Machinery Directive, when the other deployment parameters provide the best mechanical conditions.

For mixed arrays refer to your Soundvision model.

Always refer to Soundvision for the safety factor of a mixed array.

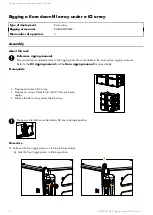

When ying a K2 array with a Kara downll, the mechanical safety of all system elements must be considered.

The indicated maximum limit applies to the KARADOWNK2 only.

Do not implement a pullback on a K2 array with a Kara downll.

K2 and Kara

conguration

rigging accessory

maximum limit

Vertical array with downll

KARADOWNK2

6 Kara

Assessing mechanical safety

Mechanical safety of the rigging system

Before any installation, always model the system in Soundvision and check the

Mechanical Data

section for

any

stress warning

or

stability warning

.

In order to assess the actual safety of any array conguration before implementation, refer to the following warnings:

Rated working load limit (WLL) is not enough

The rated WLL is an indication of the element resistance to tensile stress. For complex mechanical systems such as

loudspeaker arrays, WLLs cannot be used per se to determine the maximum number of enclosures within an array

or to assess the safety of a specic array conguration.

Mechanical modeling with Soundvision

The working load applied to each linking point, along with the corresponding safety factor, will depend on

numerous variables linked to the composition of the array (type and number of enclosures, splay angles) and the

implementation of the ying or stacking structure (number and location of ying points, site angle). This cannot be

determined without the complex mechanical modeling and calculation offered by Soundvision.

Assessing the safety with Soundvision

The overall safety factor of a specic mechanical conguration always corresponds to the lowest safety factor

among all the linking points. Always model the system conguration with the Soundvision software and check the

Mechanical Data

section to identify the weakest link and its corresponding working load. By default, a

stress

warning

will appear when the mechanical safety goes beyond the recommended safety level.

Safety of ground-stacked arrays in Soundvision

For ground-stacked arrays, a distinct

stability warning

is implemented in Soundvision. It indicates a tipping hazard

when the array is not secured to the ground, stage or platform. It is the user's responsibility to secure the array

and to ignore the warning.

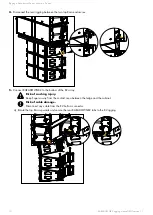

Additional safety for own arrays

When ying an array, use available holes to implement a secondary safety.

6

KARADOWNK2 rigging manual (EN) version 1.1