Rigging procedures

10.

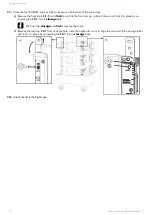

Open the four KARA#1 arms as follows (repeat on both sides of the enclosure):

a) Remove the front top R-BLP from its

storage

hole, rotate the front arm up, slide it down, and lock it in place by

re-inserting the R-BLP into its

link

hole.

A

link

hole is indicated by a yellow circle.

The front top

storage

and

link

holes are the same.

b) Remove the rear top R-BLP from its

storage

hole, slide the angle arm so as to align the cursor with the chosen

angle label, and lock it in place by re-inserting the R-BLP into the corresponding angle hole (0°/2°/4° or

1°/3°/5°/7.5°/10°).

Refer to

(p.198) to obtain the angle value corresponding to the chosen array

site angle.

a.

b.

Kara owner's manual (EN) version 1.0

125