10

NOTE:

All the BTU requirements shown in the case data are for use on parallel systems

only. A minimum of 8% excess capacity should be added to all conventional single compressor

condensing units.

NOTE:

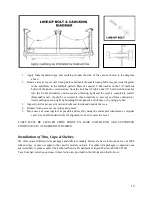

The air current is very important to the performance of these cases. The load

limit line (see load case selection) is the indicator of the inside edge of the air current and at no

time should product, signs, debris, etc. interfere with air current.

NOTE:

All electrical

data based on 115V and unlighted shelves. For lighted shelves, add 0.25

amps per shelf.

NOTE:

For sizing conventional/ individual condensing units, add 8% to BTU Load.

NOTE

: Temperature is measured in discharge air. Defrost frequency is at design conditions. Higher

temperature or humidity may require more defrost and longer fail-safes. These cases are not designed to

operate environments where the ambient temperature is greater than 75ºF and the relative humidity is

greater than 55%. Off-cycle defrost is the recommended defrost for all Q case models. Electric defrost

and hot gas defrost are available for installations requiring a positive defrost.

CAUTION

: Failure to maintain maximum design conditions may result in operational issues such

as: increased BTU load, high product temperature, coil icing, product frosting, and external sweating.

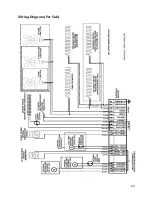

CAUTION

: Failure to properly install electrical wiring and control wiring as per wiring

diagram(s), defrost settings, and temperature set-points may result in operational issues such as:

increased BTU load, high product temperature, coil icing, product frosting, and external sweating.

Case Installation

These display cases may be installed individually or in a continuous lineup consisting of several 4’, 8’

and 12’ sections using a joint kit.

Preparation

Prepare the installation area as follows:

1.

Clean area where case is to be installed.

2.

Verify installation area is at least 15 feet from any outside entrances or heating and cooling

outlets.

3.

Verify at least 2 feet of distance between hot and cold cases.

CAUTION

:

To prevent condensation on the end panels of cases, a minimum of 6.0 inches

between walls or other cases is required for airflow. If 6.0 inches is not possible, then the space between

Summary of Contents for QILG 06

Page 2: ...2 ...

Page 7: ...7 Plan View and Cross Sections QILG Cross Section ...

Page 8: ...8 QILG Plan View ...

Page 23: ...23 Wiring Diagram Per Side ...

Page 34: ...34 ...

Page 35: ...35 ...