Step 6: Calibrate the Tool Holder

KVAL Operation Manual

4-17

Step 6: Calibrate the Tool Holder

Important: Proceed with Caution. Incorrect Calibration may damage the spindle or tool

holder. Input small increments when calibration.

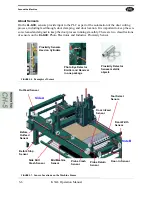

This calibration adds offsets to align the

Cutter Head Tool Holde

r to the

Tool Holder Rack

drop off

and pick up locations. For instructions about entering calibration data,

Run the

Manual Tool Changer

Control

that is located under the

Maintenance Tab

.

Check location of the

Cutter Head

Tool Holde

r against the

Tool

Holder Rack

then enter offsets into

the

X-Axis

,

Y-Axis

, and

Z-Axis

cali-

bration boxes to align to the

Tool

Holder.

About the Manual Tool Change Mode

This calibration is best used with the

Manual Tool Change Mode.

When activated, the

Cutter Head

can be moved in repeatable steps toward, away, up, and down with reference to the

Tool Holder

Rack

. At these step intervals, the operator establishes best tool position for the

Tool Holder

and

Tool Rack.

To initiate the sequence, go to the

Manual Control Tab

and locate the

Manual Tool Changer

menu.

ON/ OFF and Step Control

Select Tool

Status Message Box

Summary of Contents for DL-NCD

Page 10: ...KVAL DL NCD Operation Manual Table of Contents ...

Page 28: ...How to Download the Service Application KVAL Operation Manual 1 18 ...

Page 30: ...Safety Sign Off Sheet KVAL Operation Manual 1 20 ...

Page 62: ...About the LiteCutout Feature Detail KVAL Operation Manual 2 32 ...

Page 94: ...Appendix About Backing up the Data KVAL Operation Manual 3 32 ...

Page 118: ...Appendix Servo Motor Drive Assembly Locations KVAL Operation Manual 4 24 ...

Page 139: ...About the Electrical Panels KVAL Operation Manual 5 21 I ...

Page 142: ......

Page 143: ......