Powering Operations for the 994-X

KVAL 994-X Operation Manual

2-6

Home the 994-X

The

994-X

must go through a homing routine before any operations are performed. The homing

routine sets a zero reference from which the

994-X

measures its movement and cutting process.

If power is lost or the

994-X

is reset, the homing routine must be performed again to reset the zero

reference.

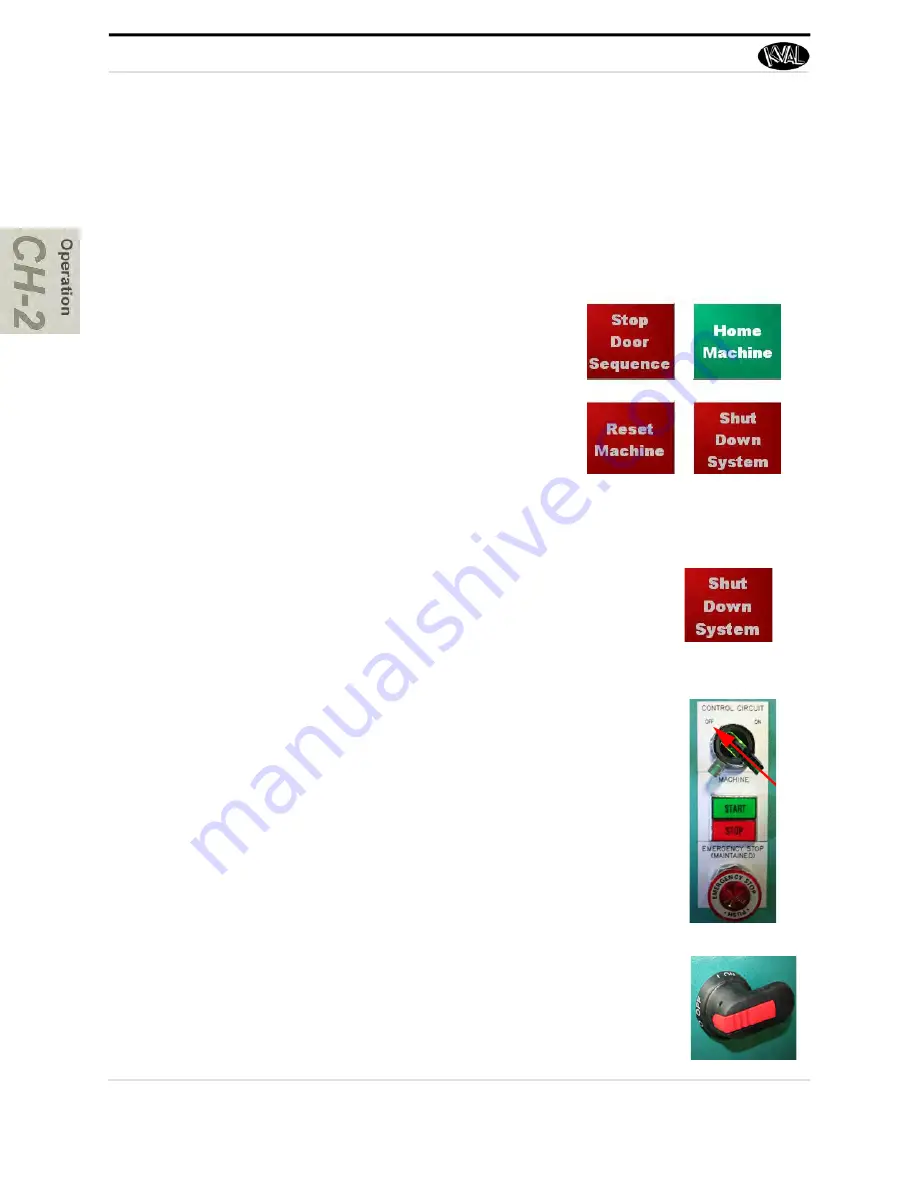

Press the

Home

button on the

Main Screen

touch screen.

How to Power Down the 994-X

1.

Select

Shut Down System

at the

Main Screen

to close oper

-

ator interface program and shut down the operating sys

-

tem.

Note:

Make sure Windows is shut down completely before

turning off the machine. Hard drive or data may be

damaged if not turned off in this order.

2.

Switch the green

Control Circuit

switch to the OFF posi

-

tion.

3.

KVAL also recommends that you turn the disconnect

switch on the electrical cabinet to OFF; this helps reduce

possible damage resulting from power surges from electri

-

cal storms.

1.

The machine will move to the home position at the

in-feed end of the machine.

2.

The machine will then move to about the middle

of its travel.

The

994-X

is now ready for work.

1

2

3

Summary of Contents for 994-X

Page 4: ...KVAL 994 X Operation Manual ...

Page 82: ...Calibration of the Back Section KVAL 994 X Operation Manual 3 22 ...

Page 124: ...KVAL 994 X Operation Manual 4 42 ...

Page 128: ...Index Kval 994 X ...

Page 129: ......