INSTALLATION

----------------------------------------------------

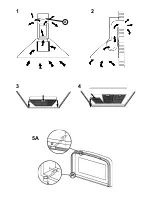

To facilitate installation, before starting remove the

grease filter/s: press inward on the clamp at the handle

and pull the filter downward (Fig. 3/4).

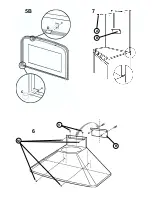

Installation of a utensil holder (upon request): see

Figure 5A or 5B depending on the model purchased. Install

the utensil holder with 4 flathead screws (supplied). Secure

the 2 supports (C) to the hood, one on the left and one on

the right; insert the utensil holder into these supports.

Keep a good grip on it until you have installed, and secured,

at least one of the 2 supports (D) at the top of the hood.

Installation on the wall (Fig. 6): using the special

drilling template, drill the required holes in the wall. As

previously specified in the chapter “Warning” remember

there must be a minimum of 650 mm between the bottom

edge of the hood and the stop of the stove. Secure the

metal bracket (B) to the wall using the screws and plugs

(bracket, screws and plugs are all supplied with the unit).

Use the 2 triangles cut into the bracket to position it precisely

along the vertical axis of the hood. Then set the hood onto

the bracket. Adjust the horizontal position, shifting the

hood to the right or left as needed lining it up with the wall

units. If the height of the hood also requires adjustment,

use the special regulation screws (V) (supplied). Once

regulation has been completed, finish securing the hood

with 4 more screws (M): mark the points for the 4 holes on

the wall, remove the hood and drill (8mm diameter holes);

then use the plugs and screws to complete installation.

Installation with rear panel (Fig. 7): the rear panel

is positioned at the top of the stove, flush against the wall.

Rest the lower edge of the panel behind the stove and

anchor the upper edge to the wall using the two holes

found on the panel. Insert the screws and plugs provided

(A). The unit is secured to the rear panel as though it were

being installed on the wall: use the supplied metal bracket

(B) and the screws and plugs supplied with the panel.

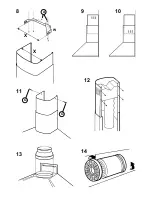

Securing the extension flues: basic installation

requirements: – Set the electrical power supply within the

space covered by the decorative flues. – If your unit is

installed in an Exhaust hood, prepare the air exhaust hole.

Adjust the width of the extension flue support bracket (W)

using screws A indicated in Fig. 8. Then use the plugs and

screws provided to secure it to the ceiling. Make certain it

is aligned with the hood. For filtering hoods, the air exhaust

grids are positioned in the upper part (Fig. 9). For exhaust

hoods, turn the upper flue over so that the air exhaust grid

is in the lower section (Fig. 10).

Exhaust hoods : connect the disposal duct to the air

evacuation pipe of the hood. Use a flexible pipe and lock

it to the air evacuation pipe of the hood with a metal hose

clamp (pipe and clamp are not provided).

Plug in the hood. Insert the telescopic flues setting them

on the hood; extend the upper flue to the ceiling and

secure with the 2 screws (G) - Fig. 11.

Filtering hood: Take the air deflector and fit a flexible pipe

to it (125 mm diameter) locking it with a metal hose clamp

(pipe and clamps are not provided). Fit the air deflector to

the upper flue (Fig. 12) with 4 screws. Install the reduction

(provided) on the hood air outlet point (Fig. 13). Take the

2 assembled extension flues and set them on the hood;

extend the upper flue to the ceiling and secure with the 2

screws (G) - Fig. 11. Extend the lower flue taping it in

place and then connect the flexible pipe to the hood

reduction. Plug in the hood. Extend the lower flue downward

setting it against the hood. Install the charcoal filters on the

side of the motor inserting them with a twisting movement

(Fig. 14).

OPERATION

----------------------------------------------------

Depending on the model, the unit is equipped with the

following controls:

Controls shown in Fig. 15:

Button A = turns the lights on/off.

Button B = turns the TIMER on/off: press once to turn the

timer on, therefore, after 5 minutes, the motor cuts out (at

the same time the selected speed blinks on the display);

the timer remains on if the motor speed is changed.

Display C =

- indicates the selected motor speed (from 1 to 4);

4: intensive speed.

- indicates Timer On when the number blinks;

- indicates Filter Alarm when the central segments is on or

blinking.

Button D = makes the motor work (at the last speed

selected); pushing the button again, the speeds of the

motor are sequentially selected from 1 to 4; keeping this

button pressed for about 2 seconds shuts down the motor.

Button R = resets the grease filters or charcoal filters;

when the filter alarm appears (i.e. when the central segment

on the display goes on), the grease filters must be cleaned

(30 hours of operation); when the central segment starts

blinking, the grease filters must be cleaned and the charcoal

filters replaced (120 hours of operation). Obviously, if the

hood is not a filtering model and does not have a charcoal

filter, clean the grease filters both when the central segment

goes on and when it starts blinking. The filter alarm can be

seen when the motor is off and for about 30 seconds. To

reset the hour counter, keep the button pressed for 2

seconds while the alarm can be seen.

Controls shown in Fig. 16/17: Switch A: LIGHT;

position 0: light off; position 1: light on. Switch B: MOTOR

SPEED: makes it possible to select the motor operating

speed; position 0: motor off. C : Motor on light.

Controls shown in Fig. 18: A = light switch. B = first

speed motor ON/OFF switch. C = second speed switch.

D = third speed switch. E = motor on light.

Controls shown in Fig. 19: Button A: turns the lights

on/off; every 30 hours of operation the corresponding pilot

lamp (S) comes on to indicate that the grease filters must

be cleaned; every 120 hours of operation the corresponding

pilot lamp (S) flashes to indicate that the grease filters must

be cleaned and the charcoal filter replaced. To restart the

hour counter (RESET), hold the button A pressed down for

about 1” (while the pilot lamp S is on). Button B: drives the

motor in first speed (the corresponding pilot lamp comes

on); when holding it down for about 1”, the motor cuts out;

when pressing the button a second time (while the pilot

lamp is on) , the TIMER is activated and thus the motor

stops after 5’ (the pilot lamp flashes).

Button C: drives the motor in second speed (the

corresponding pilot lamp comes on); when pressing the

button a second time (while the pilot lamp is on) , the

TIMER is activated and thus the motor stops after 5’ (the

pilot lamp flashes). Button D: drives the motor in third