PERIODIC SERVICE

56

C

Adjusting procedures

1. Loosen the lock nut and turn the tie rod to adjust the

rod length until the proper toe-in measurement is

obtained.

2. Retighten the lock nut.

A

Tightening torque:

74.0 to 84.0 N-m

(7.6 to 8.5 kgf-m)

(55 to 61 lbf-ft)

A

Keep the length of the left and right tie-rod equal.

B

Cleaning Spark Arrester

To avoid personal injury:

A

After operating the engine, do not touch the

muffler, exhaust pipe, or spark arrester until

they have had sufficient time to cool.

This screen type spark arrester was examined, tested,

and qualified in accordance with the USDA Forest Service

Standard 5100-1c.

C

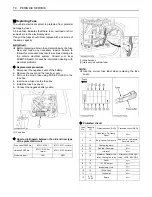

Maintenance and cleanout procedure

The screen type spark arrester should be removed,

cleaned, and inspected after every 100 hours of use.

1. The spark arrester is located inside the end of the

exhaust pipe, and is fastened with 2 bolts.

2. Unfasten the bolt and remove the spark arrester.

3. Shake loosened particles out of the screen assembly

and lightly clean the screen with a wire brush. Soak in

solvent and again clean with wire brush if necessary.

4. If any breaks in the screen or weldments are

discovered, the assembly must be replaced.

5. Return the spark arrester to the exhaust outlet, align

the bolt holes and refasten the bolt.

A

USDA approval requires clearance between spark

arrester sleeve and exhaust pipe to be no larger than

0.023" (0.584 mm).

(1) Lock nuts

(2) Tie-rod

(1) Spark arrester

(2) Bolt

(3) Muffler

Summary of Contents for RTV500

Page 13: ...5 SAFE OPERATION 1 Cardboard 2 Hydraulic line 3 Magnifying glass...

Page 14: ...SAFE OPERATION 6 7 DANGER WARNING AND CAUTION LABELS...

Page 15: ...7 SAFE OPERATION...

Page 16: ...SAFE OPERATION 8...

Page 18: ......