5 Installation/Dismantling

14 of 32

4K / 4KD

5 Installation/Dismantling

5.1 Permissible aids

▪

Lubricants

2)

–

Permanent lubricants, such as non-mineral grease (Klüber Asonic HQ 72-102)

are used for elastomers that do not serve to transmit the torque. Examples

are mating rings with an anti-twist lock or primary rings that move axially

relative to the pump components.

–

Non-permanent lubricants such as a soap solution, for example, are used for

elastomers that serve as a sealing element and, in addition, transmit the

torque. An example would be a mating ring without anti-twist lock.

▪

Recommended cleaning agent for seal faces and grub screws: ethyl alcohol

▪

Thread-locking agent: Loctite No. 243

▪

Open-ended wrench, ring spanner, socket wrench (cleaned, no impact impact

tools)

▪

Torque wrench (cleaned)

CAUTION

Impermissible cleaning agents

Damage to the seal faces at the mechanical seal!

▷

For removing minor contamination use only paper tissue and ethyl alcohol.

▷

Do not use dirty cleaning cloths or cleaning cloths that leave behind lint.

CAUTION

Impermissible assembly aids

Sealing elements made of ethylene propylene rubber perishing or swelling up!

▷

Never let sealing elements come into contact with mineral oil base lubricants.

▷

Use permissible lubricants only.

▷

Verify that the assembly aids are silicon-free.

5.2 Prerequisites

▪

The seal faces are clean and have not been touched with fingers.

▪

The mechanical seal is in proper condition and complete.

▪

The elastomers are free from any contamination, cracks, softening, hardening,

stickiness and discolouration.

▪

The mechanical seal has been placed down on a clean and level surface.

▪

The design of the connecting components (impeller, shaft, casing cover, etc.) is

suitable for the mechanical seal.

▪

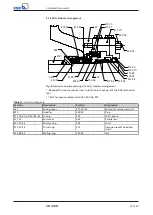

The following installation tolerances are observed:

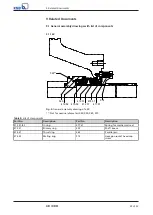

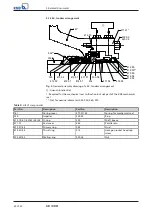

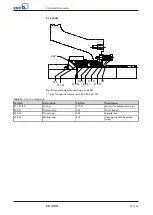

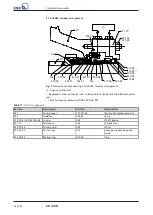

Installation tolerances

▪

Shaft run-out

–

P03ax to P06x: 0.03 mm

–

P08sx, P10ax, P12sx: 0.05 mm

▪

Axial bearing clearance: ≤ 0.2 mm

▪

Surface quality in the area of the static O-ring seal: ≥ 1.6 µm

▪

Max. vibration velocity: v ≤ 4.5 mm/s

2)

Lubricants must be compatible with all fluids used. They must not be aggressive to the secondary sealing elements.

Summary of Contents for 4K Series

Page 1: ...KSB Mechanical Seal 4K 4KD For the KWP Type Series Installation Operating Manual ...

Page 30: ......

Page 31: ......