E-2

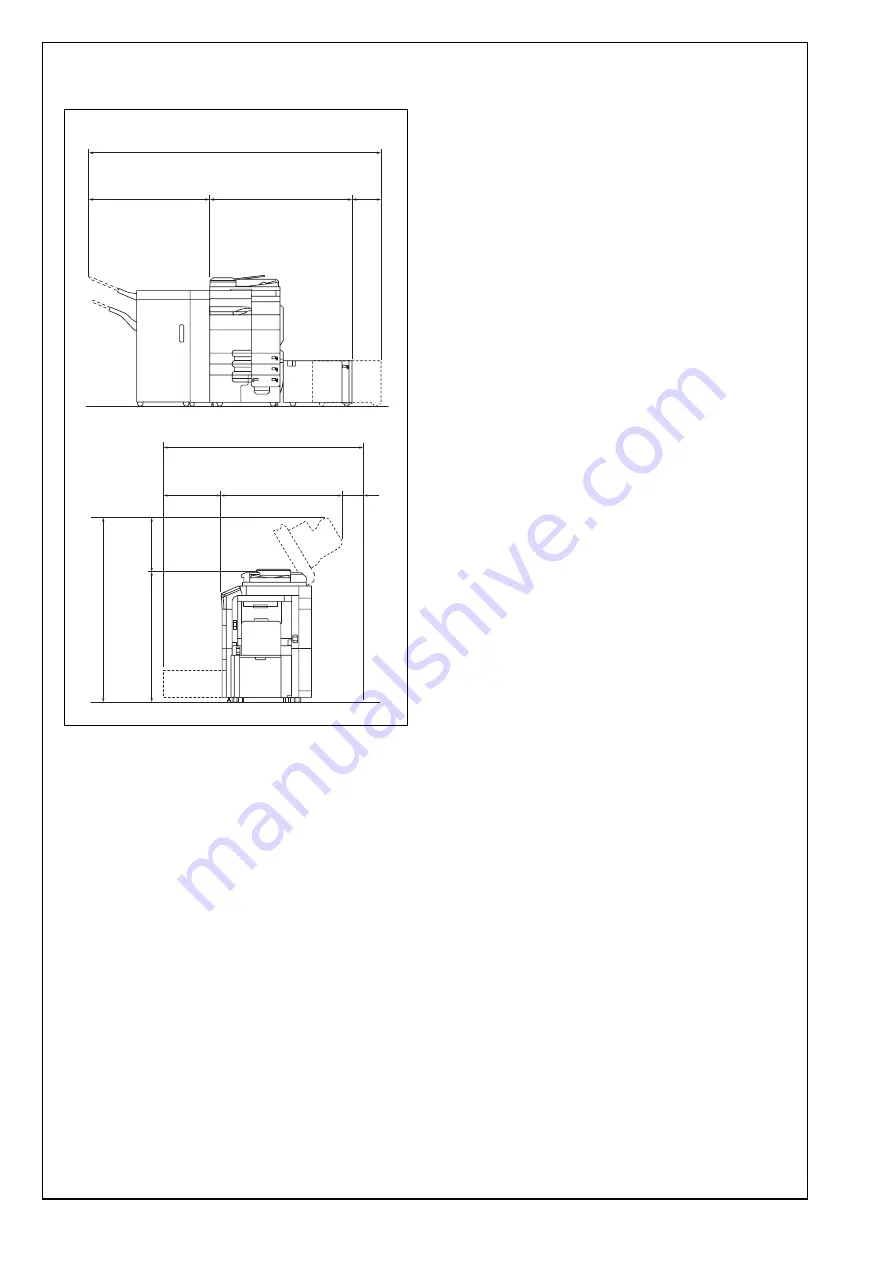

II. Installation space (unit: mm (inch))

bizhub C754 + ZU-606 + FS-535 + LU-204

III. Pre-installation check items

1. Select a level and stable place for installing the

machine.

2. Be sure to use a power source of the voltage and

frequency indicated in the product specifications.

Ensure that the current carrying capacity of the

power outlet is at least equal to the current listed

in the product specifications.

3. Power the machine directly from a dedicated

power outlet. (Do not use an extension cord.)

4. Do not plug or unplug the power cord with wet or

dirty hands, otherwise you may get an electric

shock.

5. Avoid a hot and humid environment, or a place

exposed to direct sunlight.

6. Avoid a dusty location, or a place near volatile

and flammable substances.

7. Avoid a poorly ventilated place.

IV. Notes on using touch panel

Be sure to instruct users on the following points.

• This machine uses a capacitive touch panel.

When you touch the touch panel, use your fin-

ger or the stylus pen supplied with the machine.

If you touch the panel using your nail or a pen

tip instead of using your finger or the stylus pen,

the touch panel does not respond normally.

• Pressing the touch panel hard may cause dam-

age.

• Do not strongly press the panel or press it using

the sharp tip of mechanical pencils.

• The key is a finger tapping (quick light touch

using a finger) operation.

A2X0IXC002DA

498

(19-5/8)

1027

(40-7/16)

11

55

(45-

1/2

)

495

(1

9-

1/2)

1252

(49-5/16)

1575 (62-1/16)

16

50 (

64

-1

5/1

6)

238

(9-3/8)

50

(2)

1066

(41-15/16)

2556 (100-5/8)