2.7 Connecting Power Cable

2-24

2.7

Connecting Power Cable

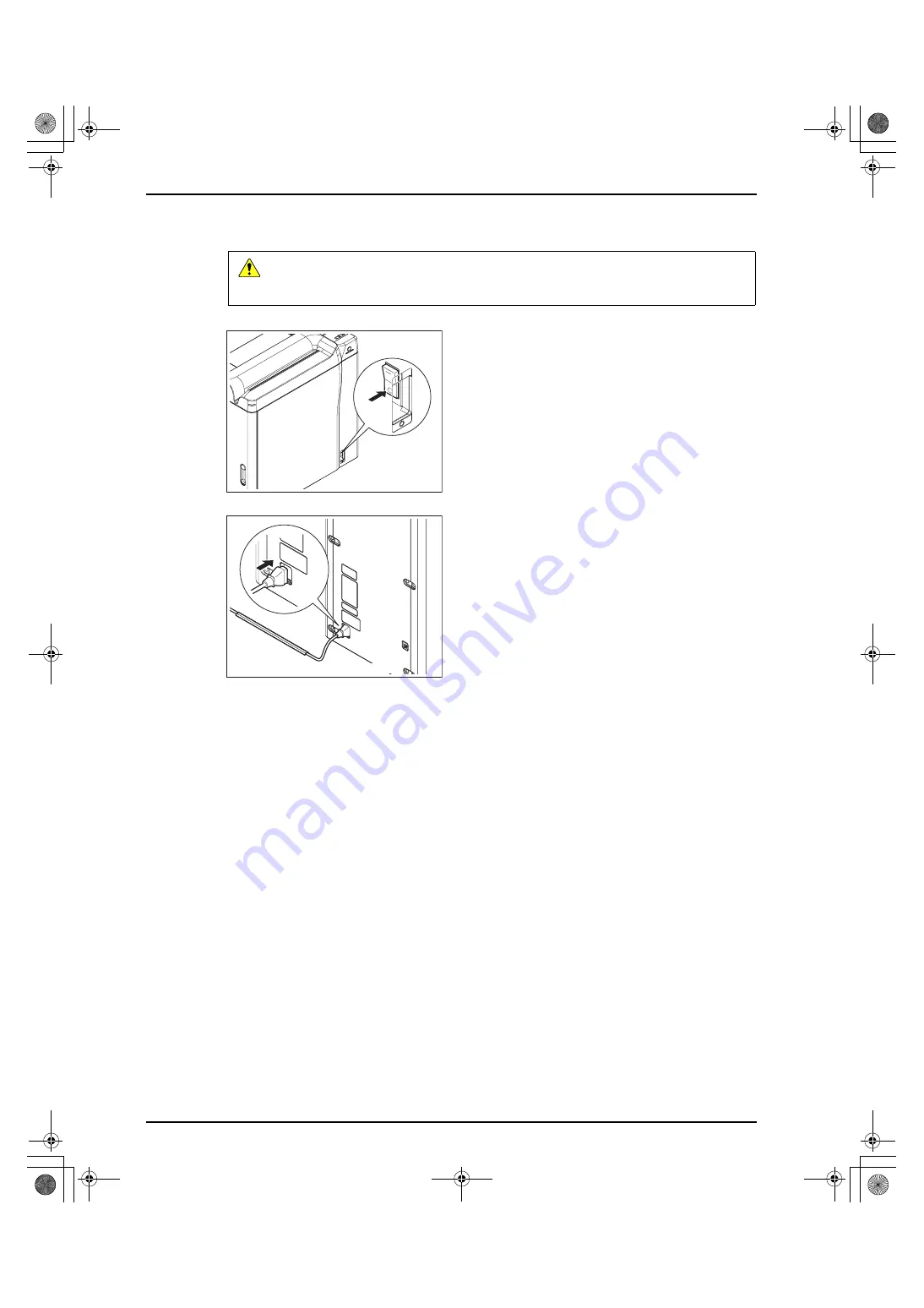

Connect the power cable that comes with the machine.

1

Check that the power breaker is turned OFF.

If the power breaker is ON, turn it OFF.

2

Connect to power cable to the power supply port.

3

Plug the power cable into the wall outlet (3P) in

the facility.

4

Fix the power cable as required by the conditions

at the installation location.

This is the final step in the process of connecting power cable.

Caution

Eliminate the clearance between the cable and the floor or wall to avoid hazards to people

walking over it.

Otherwise, someone may trip over, resulting in injury or damage to the cable or machine.

Back of the second front side

0404YF220A.book 24 ページ 2009年8月20日 木曜日 午後1時26分