96

381298/C

Procedure

1

Based on the drawings available and the physical properties of the hull, design

the sealing plate.

Make sure that the holes are made to fit the packing nuts on the transducer cables.

2

Manufacture the sealing plate according to the relevant production standards.

3

Mount the sealing plate.

4

If relevant, allow the relevant maritime authority and/or classification society to

inspect and approve the design and installation of the sealing plate.

Further requirements

If you wish to have a "dry" conduit installation, proceed to weld the steel conduit to the

top of the sealing plate.

Related topics

Installation summary, page 65

368698 Sealing plate, page 240

026925 Mounting trunk production drawing, page 243

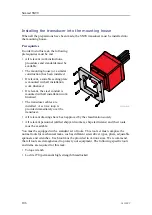

Installing the mounting house

The mounting house has been designed to offer a safe and sturdy compartment for the

SN90 transducer. It can be used for all installation options. You can insert it into a

blister, into a keel box, or into the hull. Once the transducer is installed in the mounting

house, it can also easily be removed for maintenance or replacement.

Prerequisites

In order to do this task, the following prerequisites must be met.

• All relevant vessel and transducer drawings must be available.

• All relevant work instructions, procedures and standards must be available.

• The physical location of the transducer has been determined.

• The blister or keel box has been mounted, and the design has been prepared to accept

the mounting house.

• All relevant personnel (skilled shipyard workers) and their tools must be available.

You must be equipped with a standard set of tools. This tool set must comprise the

normal tools for mechanical tasks, such as different screwdriver types, pliers, adjustable

spanners and wrenches. Each tool must be provided in various sizes. We recommend

that all tools are demagnetized to protect your equipment. Depending on the tasks at

hand, additional tools may be required. Observe the relevant rules and regulations related

to welding. The quality of the welding is critical to the safety of the vessel. Welding

must only be done by a certified welder.

Simrad SN90

Summary of Contents for Simrad SN90

Page 2: ......

Page 117: ...381298 C 115 Related topics Installation summary page 65 Installing the transducer ...

Page 236: ...234 381298 C 372915 Clamping frame Simrad SN90 ...

Page 295: ......

Page 296: ... 2016Kongsberg Maritime ISBN 978 82 8066 179 1 ...

Page 297: ......