14

476671/B

Important

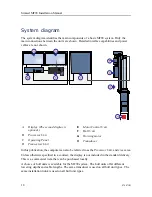

The MF90 is an advanced product. It is used with other advanced products. There is

important information that you need to know.

Watertight integrity

The size, location and design of the sonar room must fulfil all the requirements to the

vessel’s watertight integrity.

In the event of a major leak, it must be possible to close all watertight hatches and/or doors

to the room to maintain vessel stability and safety. The physical size of the sonar room must

be limited, so that in the event of a major leak, the flooding of the room will not induce

instability, or cause the vessel to capsize or sink.

For more information, see

Sonar room requirements

.

Mechanical support of the installation trunk

The installation trunk must be secured to the bulkheads and/or the hull by means of

strengthening plates (stiffereners). The dimensions and strength of the plates must be

adequate to prevent any vibrations. This is an invariable requirement to ensure the safety of

the MF90 system and the vessel.

The shape and locations of the strengthening plates must be determined by the installation

shipyard based on the physical properties of the installation trunk, the hull and the space

available. Minimum four strengthening plates must be used. Each strengthening plate must

extend all the way from the bottom to the top of the installation trunk. Only leave a small

gap to allow access to the bolts and nuts used to secure the mounting flange. The minimum

plate thickness is 10 mm, but the classification society can specify other dimensions.

Mechanical support of the hull unit gantry

The hull unit gantry must be secured to the bulkhead by means of mechanical support

brackets. The dimensions and strength of the support brackets must be adequate to prevent

vortex induced vibrations. This is an invariable requirement to ensure the safety of the

MF90 system and the vessel.

We recommend that support brackets are placed pointing at minimum three directions with

approximately 120 degrees between them.

The mechanical support brackets must be designed and manufactured by the installation

shipyard to fit the complete installation in the sonar room. All calculations made to support

the design must meet the applicable safety requirements, and apply to the physical properties

of the complete installation.

Simrad MF90 Installation Manual

Summary of Contents for Simrad MF90

Page 1: ...kongsberg com simrad Simrad MF90 INSTALLATION MANUAL...

Page 2: ......

Page 21: ...476671 B 19 Related topics Simrad MF90 page 13 Simrad MF90...

Page 369: ...476671 B 367 Drawing file...

Page 372: ...370 476671 B Simrad MF90 Installation Manual...

Page 375: ...476671 B 373 Drawing file...

Page 378: ...376 476671 B Simrad MF90 Installation Manual...

Page 384: ...382 476671 B Simrad MF90 Installation Manual...

Page 387: ...476671 B 385 Drawing file...

Page 390: ...388 476671 B Simrad MF90 Installation Manual...

Page 393: ...476671 B 391 Drawing file...

Page 398: ...396 476671 B Simrad MF90 Installation Manual...

Page 421: ......

Page 422: ...2022 Kongsberg Maritime ISBN 978 82 8066 240 8...

Page 423: ......

Page 425: ......

Page 426: ...Installation Manual Simrad MF90...