Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

57

Service and maintenance

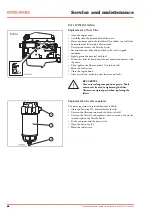

RETIGHTENING OF BOLT JOINTS, TORQUE

In order to choice exactly the correct torque, information

about the friction conditions is required.

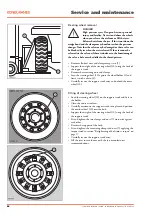

WARNING

It is important that the torque of the bolt joints

is regularly checked.

It is in particularly important that all bolts are

checked at the "first service".

WARNING

The torque of the wheel nuts must be checked

daily for the first 14 days, or until the wheels,

clamps and nuts have been tightened and no

further retightening is possible. This must be done:

• after new delivery of a machine

• after first use of the machine

• after the removal or replacement of a wheel

The bolt joints described on the following pages are to be tightened

with a torque wrench.

The chart below states the torque for bolts "slightly lubricated".

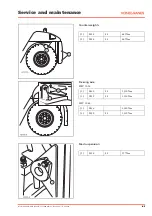

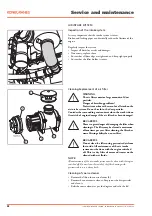

Metric thread

UTS thread

Thread

M

Strength classification

Thread

UNC

Strength classification

8.8

Nm

10.9

Nm

12.9

Nm

8.8

Nm

10.9

Nm

12.9

Nm

6

9.8

14

17

1/4"

11

15

19

8

24

33

40

5/16"

22

31

38

10

47

65

79

3/8"

38

54

68

12

81

114

136

7/16"

61

87

108

14

128

181

217

1/2"

93

131

163

16

197

277

333

9/16"

133

187

234

18

275

386

463

5/8"

183

259

323

20

385

541

649

3/4"

322

455

568

22

518

728

874

7/8"

516

729

909

24

665

935

1,120

1"

772

1,090

1,360

27

961

1,350

1,620

1 1/8"

1,090

1,550

1,930

30

1,310

1,840

2,210

1 1/4"

1,530

2,160

2,690

33

1,770

2,480

2,980

1 3/8"

2,020

2,850

3,550

36

2,280

3,210

3,850

1 1/2"

2,650

3,750

4,680