MAINTENANCE

SERVICE PROCEDURE

4-51

CHECK ALTERNATOR BELT TENSION, ADJUST

4

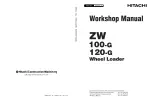

Carry out the inspection and adjustment work after removing

cover (1).

CHECKING

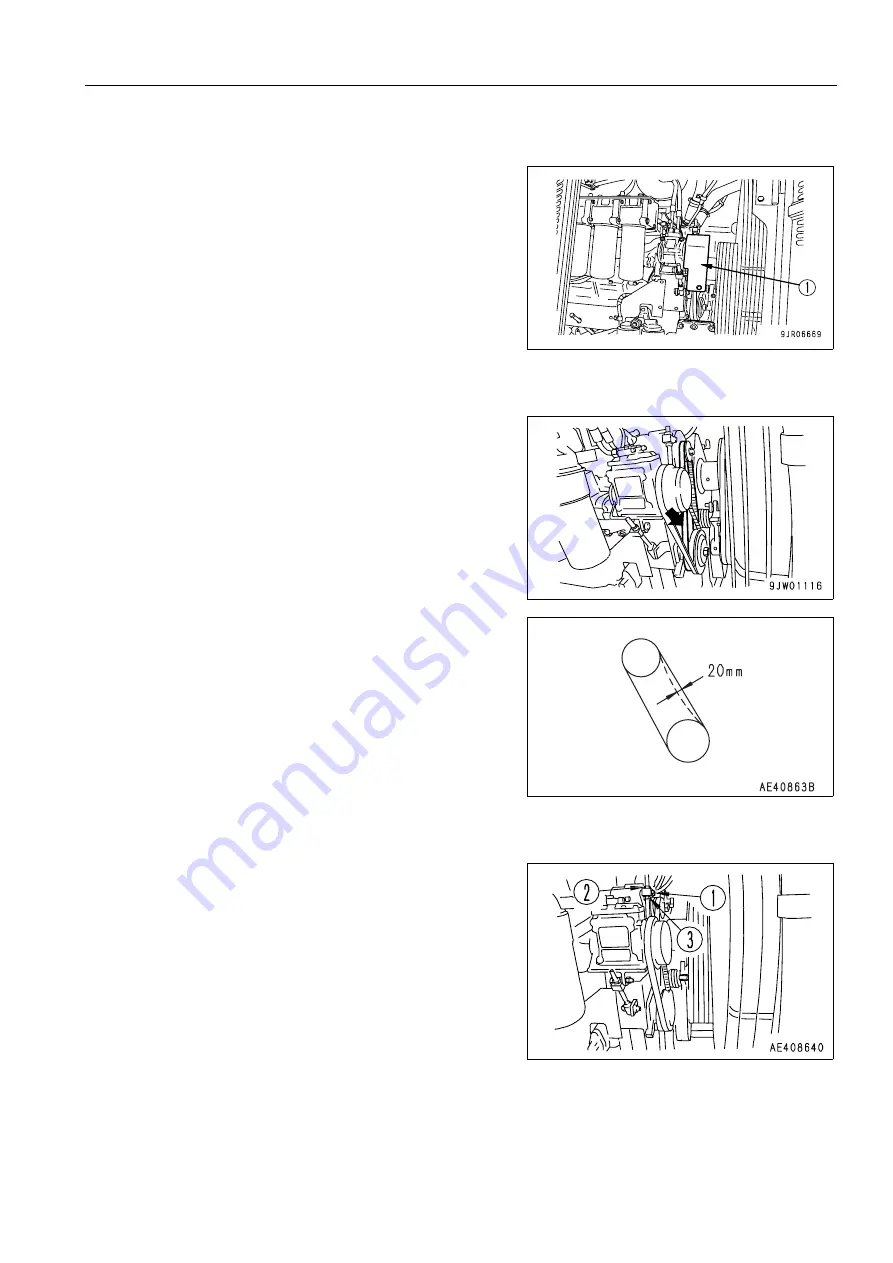

The belt should normally deflect by about 20 mm when pressed

with the finger (with a force of approx. 58.8 N (6 kg) at a point

midway between the drive pulley and alternator pulley.

ADJUSTING

1.

Loosen bolt (1) and lock nut (2).

2.

Turn adjustment nut (3) to adjust the belt tension so that

the deflection is approx. 20 mm when pressed with a finger

force of approx. 58.8 N {6 kg}.

3.

After adjusting, tighten locknut (2) and bolt (1).

4.

Check each pulley for damage, wear of the V-groove, and

wear of the V-belt. Be particularly careful to check that the

V-belt is not in contact with the bottom of the V-groove.

5.

If the belt has elongated and there is no more allowance for

adjustment, or if the belt is cut or cracked, replace the belt.

If the V-belt has been replaced with a new part, there will

be initial elongation, so inspect and adjust it again after

one-hour of operation.

Alternator pulley

Drive pulley

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...