SERVICE PROCEDURE

MAINTENANCE

4-32

REPLACE BUCKET TEETH

4

WARNING

q

It is dangerous if the work equipment moves by mistake when the teeth are being replaced.

Set the work equipment in a stable condition, stop the engine, and lock the work equipment control

levers securely with the work equipment lock lever.

q

If the pins are hit with a strong force, there is danger that the pin may fly. Make sure that there is no

person in the surrounding area.

q

Pieces may fly during the replacement operation, so always wear protective glasses, gloves, and other

protective equipment.

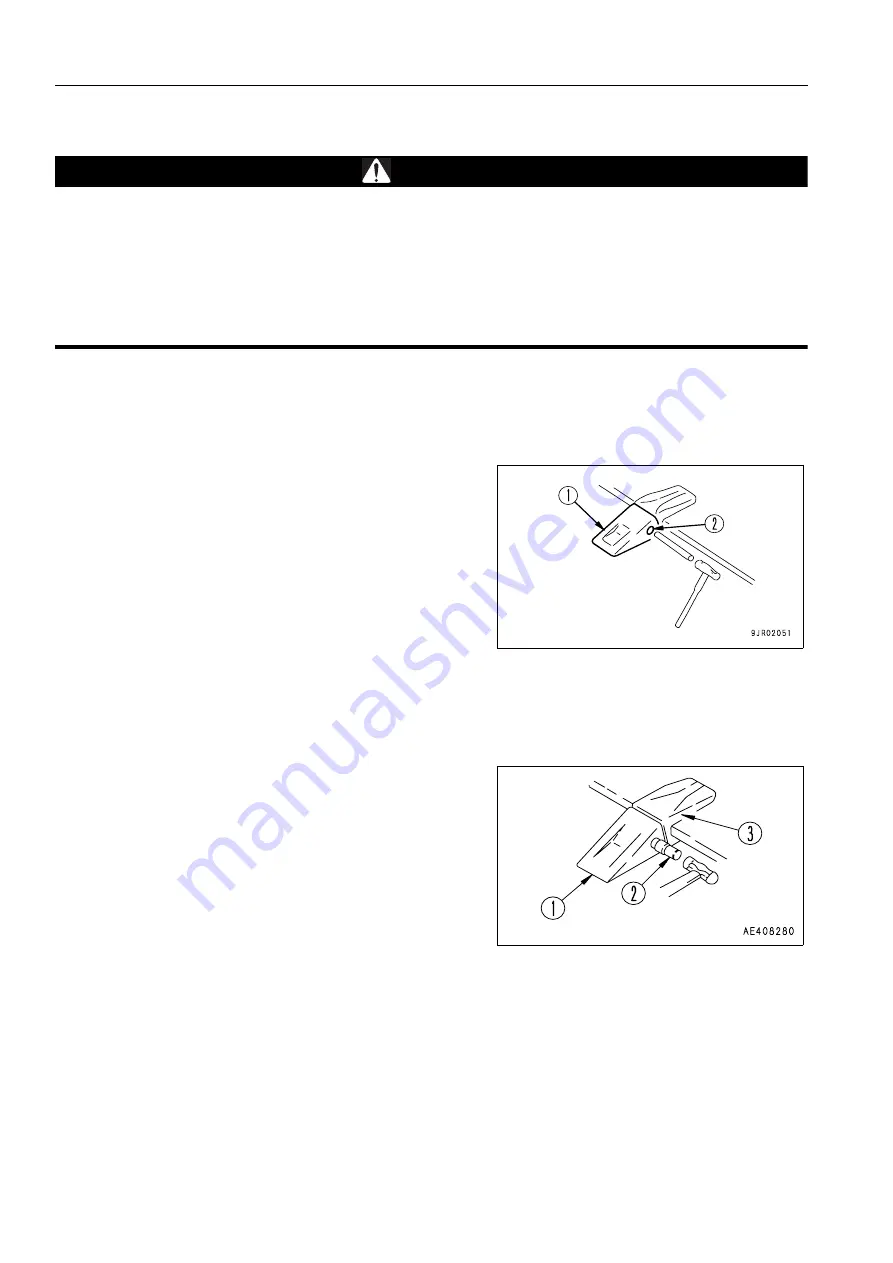

BUCKET WITH TIP TOOTH

Replace the teeth before they wear down as far as the adapter.

1.

Raise the bucket to a suitable height, then put blocks under

the bucket to keep the bottom of the bucket horizontal.

2.

Stop the engine.

3.

Remove pin (2), then remove tooth (1).

When knocking out the pin, use a bar of a diameter slightly

smaller than the pin, and knock out from the opposite side.

REMARK

If it cannot be removed by this method, for safety reasons,

always contact your Komatsu distributor to have the replace-

ment carried out.

4.

Clean bucket and adapter (3).

5.

Fit new tooth (1) in adapter (3), push in pin (2) partially by

hand, then knock it in with a hammer.

6.

After operating the machine for a few hours, check that the

pin does not come out.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...