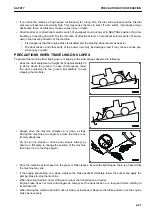

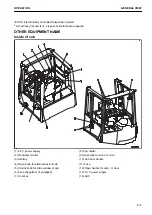

• Set frame lock bar (4) to LOCK position (L) to lock the front

and rear frame.

• After opening the rear full-length fender, set lock lever (5)

to LOCK position (L).

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

To prevent accident, do not perform maintenance with the engine running. When it is necessary to perform the

maintenance with the engine running, always observe the following.

• One worker must always sit in the operator's seat and be ready to stop the engine at any time. All workers

must maintain contact with the other workers.

• Rotating parts such as the fan, fan belt are dangerous that

they may easily catch a body part or an object someone

wears. Be careful not to come close to the rotating part.

• Never drop or insert tools or other objects into the fan, fan

belt, or other rotating parts. They may contact the rotating

parts and break, and be scattered. It is dangerous.

• If the automatic active regeneration of KDPF starts during

maintenance work, surroundings of KDPF become high

temperature.

When performing maintenance work, perform regeneration

disable of KDPF according to “HANDLE Komatsu Diesel

Particulate Filter (KDPF) (3-130)”.

• Lower the work equipment to the ground and press work

equipment lock switch (1) to lock the work equipment (pilot

lamp lights up) and prevent it from moving.

,&

PRECAUTIONS FOR MAINTENANCE

SAFETY

2-34

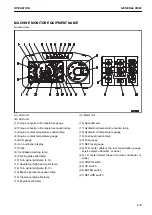

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......