PRECAUTIONS FOR LONG-TERM STORAGE

PREPARATION FOR LONG-TERM STORAGE

When putting the machine in storage for a long time (more than one month), do as follows.

• Clean and wash all parts of the machine and store it indoors. If the machine has to be stored outdoors,

select a level ground and cover the machine with waterproof sheet.

• Fill up the fuel tank. This prevents dew condensation.

• Grease the machine and change the oil before storage.

• Fill up DEF tank (Except cold weather condition).

If the inside dries up, urea is deposited and it may cause failures in component operation.

• Coat the exposed portion of the hydraulic cylinder piston rod with grease.

• After turning the starting switch to OFF position, check that the system operating lamp is not lit. Then set

the battery disconnect switch to OFF position and remove the key. When storing the battery, cover it.

For the operation of the battery disconnect switch, see “BATTERY DISCONNECT SWITCH (3-123)”.

• Lock the work equipment (the pilot lamp in the switch lights up).

• To prevent rust, fill the cooling circuit with Non-Amine Engine Coolant (AF-NAC) to give a density of at least

30% for the engine coolant.

MAINTENANCE DURING LONG-TERM STORAGE

k

k

WARNING

If it is necessary to perform the rust prevention operation while the machine is indoors, open the doors

and windows of the building to improve ventilation and prevent gas poisoning.

• During storage, perform the rust prevention operation and move the machine for a short distance once a

month so that a new film of oil will coat moving parts. At the same time, charge the battery as well.

• When operating the work equipment, wipe off all the grease from the hydraulic cylinder piston rods.

• If the machine is equipped with an air conditioner, operate the air conditioner for 3 to 5 minutes once a

month to lubricate all parts of the air conditioner compressor. Always run the engine at low idle when doing

this. In addition, check the refrigerant level twice a year.

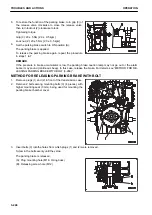

Procedure for rust prevention operation

1.

Check the safety around the machine, and check for any problem on the machine (leakage of coolant and

oil).

2.

Check the oil level and coolant level on each part.

Check them in the following order.

(1) Reservoir tank coolant level

(2) Engine oil level

(3) Hydraulic oil level

3.

Start the engine and run it at low idle for 5 minutes.

4.

Check for abnormality on the machine monitor and machine.

If any abnormality (noise, vibration, etc.) is found, stop the engine immediately, and ask your Komatsu dis-

tributor for inspection and maintenance.

5.

Check the oil level in the transfer or transmission.

6.

Depress the accelerator pedal to the midpoint in order to run the engine at a medium speed, and fully ex-

tend and fully retract each hydraulic cylinder repeatedly 5 times.

7.

To lubricate the axle, drive the machine forward and reverse (forward and reverse travel of 10 m for 3

times).

8.

Set the machine in the parking posture and stop the engine to park the machine.

OPERATION

PRECAUTIONS FOR LONG-TERM STORAGE

3-241

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......