Blasted rock

4.

At the same time as the bucket thrusts into the target ma-

terial, raise the boom to prevent the bucket from going in

too far. Raising the boom allows the front wheels to exert

sufficient traction.

If the bucket thrusts too much and, as a result, rising of the

boom or forward travel of the machine is stopped, release

the accelerator pedal somewhat. Proper operation of the

accelerator pedal for each type of the soil is effective for

saving of fuel and prevention of wear of the tires.

5.

Check that enough material is loaded into the bucket, then

operate the bucket control lever to repeat tilting back the

bucket and load the bucket fully.

If the bucket edge is moved up and down while digging

with the bucket by using rim pull, the front tires will come

off the ground and this will cause the tire slippage.

6.

If too much material is loaded in the bucket, perform quick

DUMP and TILT operation of the bucket to shake off the

excessive load so that the load does not spill during haul-

ing.

DIG AND LOAD ON HORIZONTAL SURFACE

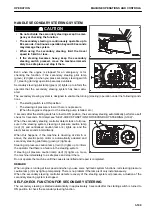

• When digging the ground in digging and loading work on a level ground, set the bucket cutting edge facing

down slightly as follows and drive the machine forward. Always be careful not to load the bucket on one

side.

• The 1st gear speed is recommended.

k

k

CAUTION

Do not set the bucket cutting edge downward more than 20 °.

MACHINE OPERATIONS AND CONTROLS

OPERATION

3-208

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

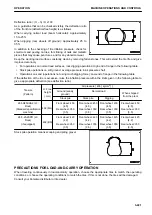

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......