METHOD FOR BLEEDING AIR FROM HYDRAULIC CIRCUIT

METHOD FOR BLEEDING AIR FROM PUMP

Perform it when any hydraulic component or oil has been replaced.

NOTICE

If the pump is operated without filling the pump case with hydraulic oil, abnormal heat will be generated

and this may cause a premature damage to the pump. Bleed air securely.

1.

Run the engine at low idle.

2.

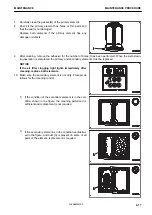

Open the rear right cover.

3.

Loosen the cap (1) on the pump by 1 turn and check that

the oil comes out.

4.

Having bled the air, tighten the cap (1).

Tightening torque: 9,8-12,7 Nm (1,0-1,3 kgm)

METHOD FOR BLEEDING AIR FROM PUMP AND HYDRAULIC TANK

Perform it when any hydraulic component or oil has been replaced.

NOTICE

If you run the engine at high speed without bleeding air from the piping between the pump and hydraul-

ic tank, the pump may heat abnormally and may be broken in a short period.

1.

Start the engine and run at medium speed.

2.

Operate the work equipment slowly for approximately 5 minutes, and bleed air.

METHOD FOR BLEEDING AIR FROM CYLINDER

Perform it when any hydraulic component or oil has been replaced.

NOTICE

If the engine runs at high speed immediately after startup or a cylinder is pushed up to its stroke end,

air mixed into the cylinder may cause damage to the piston packing or etc.

1.

Start the engine and run it at low idle.

2.

With the engine idling, extend and retract each cylinder 4 to 5 times, taking care that a cylinder is not

moved to the stroke end. (Stop the cylinder approximately 100 mm short of its stroke end.)

3.

Operate each cylinder 4 to 5 times to each stroke end.

All air is bled.

METHOD FOR BLEEDING AIR FROM SWING MOTOR

Bleed air only when the oil in the swing motor case is drained.

NOTICE

If the air is not bled from the swing motor, the motor bearings may be damaged.

RKA65210

MAINTENANCE

MAINTENANCE PROCEDURE

4-31

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......