METHOD FOR CHECKING WINDOW WASHER FLUID LEVEL, ADDING FLUID

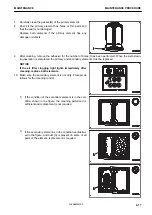

If air is in the window washer fluid, check the fluid level in window washer tank (1).

1.

Check the fluid level in window washer tank (1).

2.

If the level is low, add window washer fluid for automobile.

Be careful not to let dirt or dust get in when adding fluid.

Mixture ratio of pure washer fluid and water

The proper mixing proportion varies with the ambient temperature. Add washer fluid diluted with water at the

following proportion.

Area, season

Mixing proportion

Freezing temperature

Normal

Washer fluid 1/3: water 2/3 -10 °C

Winter in cold district

Washer fluid 1/2: water 1/2 -20 °C

Winter in extremely cold district Pure washer fluid

-30 °C

There are 2 types depending on the freezing temperature: -10 °C (general use) and -30 °C (cold district use),

select according to the area and season.

METHOD FOR CHECKING AND MAINTENANCE AIR CONDITIONER

Check and maintenance items

Some maintenance items of the air conditioner need to be inspected periodically and the others are performed

irregularly. Inspect and service the air conditioner according to the following list to use it effectively.

Control

and

maintenance

points

Content of check and maintenance

Guideline

for

mainte-

nance interval

Refrigerant (gas)

Charge quantity

Twice a year (spring, au-

tumn)

Air conditioner condenser

Fins blocked

Every 500 hours

Compressor

Operating condition

V-belt

Damage, tension

Every 250 hours

Blower motor, fan

Operating conditions (can strange noises be heard?) When required

Control mechanism

Operating conditions (is it operating normally?)

When required

Piping connections

Mounting condition, looseness at tightening or con-

necting portions, leakage of gas, damage

When required

Even during the off-season, operate the air conditioner for 3 to 5 minutes once a month to maintain the oil film at

all parts of the compressor.

RKA65160

MAINTENANCE

MAINTENANCE PROCEDURE

4-25

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......