• Clean and replace the fuel filter frequently.

• Clean electrical components, especially the starting motor and alternator, to avoid accumulation of dust.

• When checking and replacing the oil or filters, move the machine to a place where there is no dust and take

care to prevent dust from entering the system.

AVOID MIXING OIL

Never mix different brand or grade of oil. If a different brand or grade of oil has to be added, drain the old oil and

replace all the oil with the new brand or grade of oil.

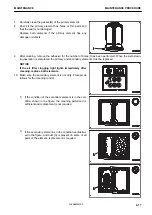

LOCKING INSPECTION COVERS

When opening the covers, place the catch in the locking position .

If inspection or maintenance operations are carried out with the covers incorrectly blocked, there is a risk that

they may close unexpectedly because of the wind and injure the operator. For details, see OPERATION “METH-

OD FOR OPENING AND CLOSING COVERS WITH LOCK”.

BLEED AIR FROM HYDRAULIC CIRCUIT

When hydraulic equipment is repaired or replaced, or the hydraulic piping is disconnected, the air must be bled

from the circuit.

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

• When removing parts at locations where there are O-rings or gasket seals, clean the mounting surface, and

replace them with new parts.

When doing this, be careful not to forget to assemble O-rings and gaskets.

• When installing the hoses, do not twist them or bend them sharply.

If they are installed so, their service life will be extremely shortened and they may be damaged.

CHECKS AFTER INSPECTION AND MAINTENANCE

If you forget to perform the inspection and maintenance, unexpected problems may occur, and this may lead to

personal injury. Always observe the followings.

Checks after operation (with engine stopped)

• Have any inspection and maintenance points been forgotten?

• Have all inspection and maintenance items been performed correctly?

• Have any tools or parts been dropped inside the machine? It is particularly dangerous if parts are dropped

inside the machine and get caught in the lever linkage mechanism.

• Are there any leakage of coolant or oil? Have all nuts and bolts been tightened?

Checks while the engine is running

• For the checks when the engine is running, see SAFETY INFORMATION, “TWO WORKERS FOR MAIN-

TENANCE WHEN ENGINE IS RUNNING” and pay attention to safety.

• Increase the engine speed to check for the leakage of fuel or oil.

• Check if the inspected and serviced area is normally operated.

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

It is necessary to select fuel or lubricant according to the ambient temperature.

For details, see “RECOMMENDED FUEL, COOLANT, AND LUBRICANT (7-5)”.

MAINTENANCE

PRECAUTIONS FOR MAINTENANCE

4-3

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......