6.

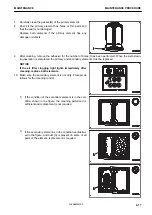

Place a container under the pipe connected to the tap (6).

7.

Open the tap (6) at the bottom of the radiator.

8.

Having discharged the coolant, close the tap (6) and add

tap water until the radiator is full.

9.

Start the engine.

10. To complete the warm-up operation of the hydraulic equip-

ment more quickly, set the working mode to P mode

(heavy-duty mode).

11. Move the lock lever slowly to FREE position (F).

12. Raise the bucket from the ground.

13. Turn the fuel control dial to a point of 2/3 between Low idle

(MIN) position and High idle (MAX) position.

14. Operate the work equipment control levers according to

the following procedure.

NOTICE

When the work equipment is operated, take care that it

does not interfere with the machine or ground.

1) Move the R.H. work equipment control lever slowly in

the direction to the bucket CURL side (D). Operate the

lever to the end of its stroke and hold it in position for

30 seconds.

2) Move R.H. work equipment control lever (5) slowly in

the direction bucket DUMP position (C). Operate the lever to the end of its stroke and hold it in position

for 30 seconds.

RKA65150

RKA61230

RKA48690

MAINTENANCE

MAINTENANCE PROCEDURE

4-21

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......