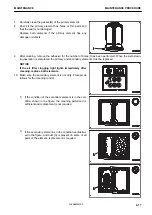

4.

Remove the accumulated dust in the air filter housing and

cover (5) and clean with a cloth. Pay particular attention to

the cleaning of the corners and the seal of the filter.

5.

Remove the secondary element (4) and replace it immedi-

ately with a new one.

6.

Fit the primary element (3).

7.

Check the integrity of the cover (2) gasket (5). Replace

with a new one if necessary.

8.

Fit the cover (2).

COOLANT REPLACEMENT METHOD

k

k

WARNING

• Immediately after the engine is stopped, the coolant is still hot and the pressure is accumulated in

the radiator. If the cap is removed in this condition and the coolant is discharged, it may cause

burns. Wait for the temperature of the coolant to go down, and then turn the cap slowly to release

the pressure.

• For further details on engine start-up, see OPERATION “CHECKS AND ADJUSTMENT BEFORE

STARTING ENGINE” and “ENGINE START-UP METHOD”.

• Since the engine is running during the discharge, it is dangerous to stand to the rear of the machine

which could be accidentally moved. Never enter the rear of the machine when the engine is running.

Place the machine on a level ground when changing the coolant.

Replace the coolant as per the table.

Coolant .

Coolant replacement interval

Non-Amine Engine Coolant

(AF-NAC)

Every 2 years or 4000 hours, whichever comes

sooner

The coolant has the important function of preventing corrosion as well as preventing freezing.

Even in the areas where freezing is not an issue, the use of coolant is essential.

Komatsu machines are supplied with Non-Amine Engine Coolant (AF-NAC). Non-Amine Engine Coolant (AF-

NAC) has excellent anticorrosion, antifreeze and cooling properties and can be used continuously for 2 years or

4000 hours.

Komatsu recommends the use of Non-Amine Engine Coolant (AF-NAC) as coolant. If another coolant is used,

you may experience serious problems such as corrosion of the engine and the aluminium components of the

cooling system.

To maintain the anticorrosion properties of Non-Amine Engine Coolant (AF-NAC), always keep the density of

Non-Amine Engine Coolant between 30% and 64%.

Non-Amine Engine Coolant (AF-NAC) is already diluted with distilled water. When using the coolant, investigate

the lowest temperature in the past and decide the density for the coolant from the coolant density table below.

When exactly deciding the density of the coolant, set a temperature 10 °C lower than the lowest temperature of

the working area.

The coolant density varies according to the ambient temperature, but it must be over 30% at least.

Mixing proportion of tap water and coolant

Min. atmospheric tem-

perature

°C

Min. -10

-15

-20

-25

-30

-35

-40

-45

-50

Concentration (%)

30

36

41

46

50

54

58

61

64

MAINTENANCE

MAINTENANCE PROCEDURE

4-19

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......