MAINTENANCE PROCEDURE

INITIAL 50 HOURS MAINTENANCE (ONLY AFTER THE FIRST 50 HOURS)

Check the wheel nuts tightening For details, see “METHOD FOR CHECKING WHEEL NUT TIGHTENING

(4-32)”

Only for machines in which synthetic biodegradable oil HEES is used

Replace the hydraulic oil filter component.

For details about the replacement method, see the section MAINTENANCE EVERY 1000 HOURS.

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250

HOURS)

Carry out the following maintenance operations after the first 250 hours of work.

• Change the gear oil.

• Change the rear axle oil.

• Change the front axle oil.

For details about the replacement method, see the section MAINTENANCE EVERY 1000 HOURS.

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500

HOURS)

Only for machines in which synthetic biodegradable oil HEES is used

Change the hydraulic oil and clean the intake filter.

For details about the replacement method, see the section MAINTENANCE EVERY 1000 HOURS.

WHEN REQUIRED

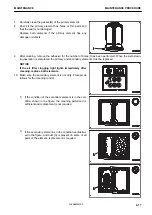

METHOD FOR CHECKING, CLEANING AND REPLACING AIR CLEANER

k

k

WARNING

• If inspection, cleaning, or maintenance is performed while the engine is running, dust enters into

the engine and damages it. Be sure to stop the engine before performing these works.

• When using compressed air, there is a danger that dirt may scatter and cause personal injury. Wear

the protective equipment such as protective eyeglasses and dust mask.

• When working on a high place or in the place where the foothold is poor, be careful not to fall be-

cause of the reaction when pulling out the outer element.

NOTICE

If the air cleaner is not cleaned or maintained sufficiently, the mass air flow sensor which is installed to

the air cleaner does not function correctly, and it may cause a decrease in the engine performance.

METHOD FOR CHECKING AIR CLEANER

The air cleaner clogging caution lamp informs when the air cleaner element should be checked.

MAINTENANCE PROCEDURE

MAINTENANCE

4-14

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......