Electrolyte temper-

ature

Percentage (%)

20 °C

0 °C

-10 °C

-20 °C

100

1.28

1.29

1.30

1.31

90

1.26

1.27

1.28

1.29

80

1.24

1.25

1.26

1.27

75

1.23

1.24

1.25

1.26

• Since the capacity of the battery decreases considerably at low temperatures, cover the battery or remove

it from the machine, store it in a warm place and install it again the following morning.

• If the electrolyte level is low, add distilled water before starting work. Do not add water at the end of the

working day, as the battery electrolyte may freeze overnight.

PRECAUTIONS AFTER DAILY WORK COMPLETION

k

k

WARNING

Performing idling of the wheels is dangerous, stay well away from the wheels.

To prevent mud, water, or the undercarriage from freezing and making it impossible for the machine to move on

the following morning, observe the following precautions.

• Remove all the mud and water on the machine. In particular, wipe the hydraulic cylinder rods clean to pre-

vent damage to the seal caused by mud, dirt, or drops of water on the rod from getting inside the seal.

• Park the machine on a firm, dry ground.

If this is not possible, position it on wooden planks to avoid the wheel icing on the ground, thus making

starting up difficult next morning.

• Open the drain valve and drain any water collected in the fuel system to prevent it from freezing.

• Fill up the fuel tank. This will reduce the formation of condensation in the tank when the temperature falls.

• After operation in water or mud, remove water from undercarriage according to the procedure to extend un-

dercarriage service life.

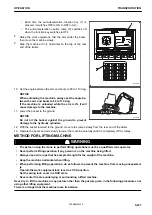

1.

Put the engine at a low speed and turn the turret 90 °

to bring the work equipment to the side of the wheels.

2.

Set the machine in the posture shown in the figure.

1) Rotate the turret by 90° with engine idling, and

move the working equipment on the wheels side.

2) Lift the machine using the stabilizers until the

wheels are slightly raised from the ground.

3.

Let the wheels spin at idle.

4.

Repeat this procedure on both the left and the right

side of the machine.

AFTER COLD WEATHER SEASON

When the season changes and the weather becomes warmer, do as follows.

Replace the fuel and oil for all equipment with the ones of the specified viscosity. For details, see “METHOD

FOR USING FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE”.

COLD WEATHER OPERATION

OPERATION

3-240

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......