NOTICE

After removing the pins, make sure that mud or sand does not get on them. Dust seals are fitted at both

ends of the bushings, be careful not to damage them.

2.

Remove the double nut of stopper bolt at arm pin (A) and

link pin (B), then pull out the bolts.

3.

Pull out arm pin (A) and link pin (B), then remove the buck-

et.

4.

Invert the removed bucket.

5.

Align arm (5) with mounting hole (1) of link (6).

6.

Align link (6) with mounting hole (2) of arm (5).

7.

Insert grease-coated pins (A) and (B) into hole (1) and

hole (2) respectively.

REMARK

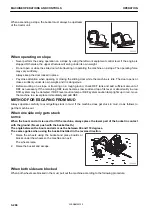

Fit O-ring (3) to mounting portion (1) of arm (5) and bucket

(4).

Fit O-ring (3) to arm (5) as shown in the figure since it is

damaged easily when bucket (4) is installed.

After inserting the pin, fit it in the regular groove.

8.

Install the lock bolt and nut of each pin.

9.

Apply grease to each pin.

REMARK

• Lubricate with grease thoroughly until the grease comes out from the end faces.

• When replacing the bucket, replace the dust seal with a new one if it is damaged. If a damaged seal is

used without being replaced, sand and dirt may enter the pin portion and cause abnormal wear of the

pin.

MACHINE OPERATIONS AND CONTROLS

OPERATION

3-212

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......