METHOD FOR CHECKING AND CLEANING RADIATOR FINS, OIL COOLER FINS,

FUEL COOLER FINS, AND AIR CONDITIONER CONDENSER FINS

k

k

WARNING

If the compressed air, high-pressure water, or steam hits your body directly or dirt is scattered by use of

it, there is a danger of personal injury.

Wear the protective equipment such as the protective eyeglasses and dust mask.

NOTICE

• When using compressed air for cleaning, blow it from some distance as perpendicular to the core

as possible to avoid damaging the fins. Damage on the fins can cause water leakage and overheat-

ing.

• In a dusty job site, check the fins every day, regardless of the maintenance interval.

1.

Open engine hood (1).

2.

Securely lock the hood with hood support lever (2).

3.

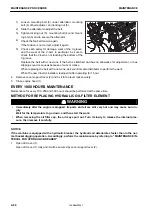

Check the front and rear sides of radiator fins (3), oil cooler

fins (4), fuel cooler fins (5), and condenser fins (6). If there

is any mud, dirt, leaves, etc. stuck to the fins, blow it off

with compressed air.

NOTICE

Steam or water may be used instead of the com-

pressed air. However, when performing powerful

steam cleaning (high-pressure machine wash) of the

heat exchange equipment (radiator, oil cooler and fuel

cooler), maintain sufficient distance from the machine

when performing the work.

If steam cleaning (high-pressure machine wash) is per-

formed at close distance, there is a danger that the in-

ternal fins of the heat exchange equipment will be de-

formed, and this will cause early clogging and break-

age of the equipment.

4.

Visually check the rubber hose connected to the heat ex-

change equipment.

If the rubber hose is cracked or become fragile, ask your

Komatsu distributor for replacement.

5.

Check the hose clamps for looseness.

If the hose clamps are loosened, tighten them.

6.

Remove hood support lever (2) and fix it to the lever lock securely.

7.

Close engine hood (1).

RKA68180

RKA68970

MAINTENANCE PROCEDURE

MAINTENANCE

4-56

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......