1) Tighten the bolt in the order shown in the figure.

Tightening torque:

117 to 216 Nm {18 to 22 kgm}

2) Check that the nut and shoe are in close contact with the

link contact surface.

METHOD FOR CHECKING AND ADJUSTING STEEL SHOES AND ROADLINERS

TRACK TENSION

The wear of the pins and bushings of the undercarriage depends on the working condition and soil condition.

Check the track tension occasionally and keep it in the standard range.

Perform check and adjustment on a level and firm ground.

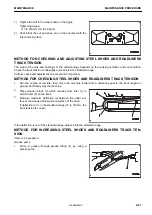

METHOD FOR CHECKING STEEL SHOES AND ROADLINERS TRACK TENSION

1.

Run the engine at low idle, then move the machine forward for a distance equal to the track length on

ground, and slowly stop the machine.

2.

Place wooden block (3) which reaches from idler (1) to

carrier roller (2) on the track.

3.

Measure maximum deflection (a) between the under sur-

face of the wooden block and top surface of the track.

If deflection (a) is in the standard range (10 to 30 mm), the

track tension is correct.

If the deflection is out of the standard range, adjust it into the standard range.

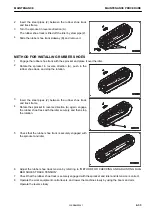

METHOD FOR INCREASING STEEL SHOES AND ROADLINERS TRACK TEN-

SION

Items to be prepared

Grease pump

1.

Pump in grease through grease fitting (4) by using a

grease pump.

MAINTENANCE

MAINTENANCE PROCEDURE

4-27

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......