7.

Turn the transparent cup (6) counterclockwise to remove it.

Remove the transparent cup (6) without spilling the fuel.

If the fuel spills, wipe them off with cloth thoroughly.

Be careful not to lose the red ring in transparent cup (6).

8.

Remove the element (7) from top of the fuel prefilter.

9.

Clean the inside of transparent cup (6) and element (7)

with diesel fuel or flushing oil.

10. After cleaning, install the element (7) and O-ring (8) to

transparent cup (6).

11. Insert the red ring into transparent cup (6) and fill it with

fuel.

12. Check the condition of O-ring (8) installed to transparent

cup (6).

Replace the O-ring with a new one if needed.

13. Install the transparent cup (6) to top of fuel prefilter, and

tighten it clockwise.

Tightening torque:

30 Nm {3.05 kgm}

14. Turn the handle (4) to OPEN position (O).

15. After the cleaning of element is completed, bleed air from

the fuel circuit.

For bleeding air, see OPERATION “PROCEDURES FOR

BLEEDING AIR FROM FUEL CIRCUIT”.

16. Remove cover support lever (2) and fix it to the lever lock

securely.

17. Close engine hood (1).

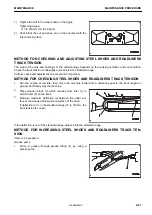

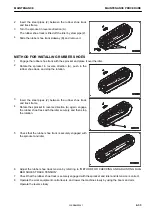

METHOD FOR CHECKING LOOSENESS AND TIGHTENING STEEL TRACK SHOE

BOLTS

NOTICE

If the machine is used with steel shoe bolts loose, they will break. If any looseness of the shoe bolt is

found, retighten it.

RKA68194

RKA68760

RKA68195

RKA68196

MAINTENANCE

MAINTENANCE PROCEDURE

4-25

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......